The new edge-first system integrates industrial AI software with GPU-accelerated infrastructure to reduce latency, protect data, and fast-track adoption across manufacturing clusters.

India’s push to embed artificial intelligence into factories and critical infrastructure is getting a new edge-focused boost with the launch of YodaEdge, a pre-integrated platform designed to run AI workloads directly on-site rather than in distant cloud environments by Altos Computing Inc.

The key features are:

- Edge-first, on-premises AI architecture for low latency and data sovereignty

- Pre-integrated industrial AI software and GPU-accelerated infrastructure

- Support for vision, language and generative AI workloads locally

- Built for factory floors and distributed infrastructure environments

- Optimised for rapid deployment and measurable operational ROI

The system combines the Orion industrial AI stack from Industry.AI with edge-optimised infrastructure from Altos Computing Ltd, powered by accelerated computing from NVIDIA. The goal: deliver enterprise-grade AI performance at the point of action on factory floors, in logistics hubs, and across distributed urban infrastructure.

The platform arrives as manufacturers and MSMEs face growing pressure to improve productivity, reduce downtime and comply with safety norms, while also meeting India’s data localisation and digital sovereignty priorities. Cloud dependency, latency issues and data security concerns have slowed AI adoption in these environments. YodaEdge addresses those constraints with an on-premises, edge-first architecture that keeps sensitive operational data local and enables real-time decision-making.

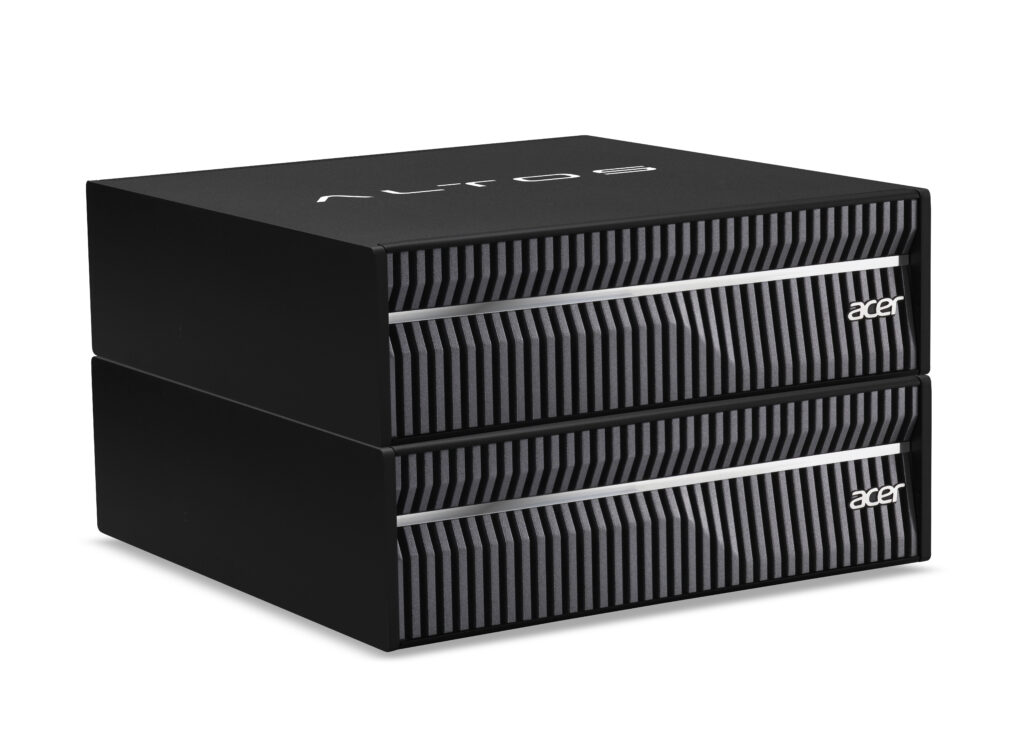

Packaged as an “AI in a Box” deployment, the solution integrates hardware, GPUs and AI software into a single stack, allowing enterprises to operationalise AI without building complex infrastructure from scratch. The architecture supports computer vision, predictive analytics and generative AI workloads in live industrial settings.

Designed specifically for rugged, real-world environments, the platform supports use cases such as real-time safety monitoring, predictive maintenance and AI-powered knowledge assistants that provide instant access to operating procedures and maintenance histories. Industry benchmarks suggest AI-enabled safety systems can significantly cut workplace incidents, while predictive maintenance models can reduce unplanned downtime.

The offering also targets India’s MSME segment, aiming to lower deployment barriers and shorten implementation cycles so smaller manufacturers can adopt AI within operational budgets. As adoption expands across manufacturing clusters and infrastructure projects, the edge-centric approach positions AI as embedded industrial intelligence rather than a remote cloud service.