EROM thermal model library brings higher simulation accuracy, broader shunt resistor support, and native integration with Siemens’ Flotherm—giving engineers faster, more reliable thermal analysis for automotive and industrial systems.

Engineers working on high-reliability automotive and industrial systems now have access to more precise thermal simulation tools, with ROHM expanding its EROM (Embeddable BCI-ROM) model library for shunt resistors. The enhancement—now standard in Siemens’ latest Simcenter Flotherm thermal design suite—aims squarely at shrinking the gap between real-world heat behavior and digital simulation, a pain point in power-dense designs.

At the center of this update is the addition of the company’s PMR shunt resistor family to the existing EROM library, which previously supported the company’s PSR lineup. These low-ohmic resistors are widely used for current sensing in automotive ECUs, industrial motor drives, battery systems and power-management modules, environments where even small thermal miscalculations can impact accuracy, drift, and long-term reliability.

The key features are:

- ±5% accuracy for surface temperature and thermal resistance.

- Models now include both PSR and PMR shunt resistor series.

- Built-in support in Simcenter Flotherm 2510 and later.

- Fast reduced-order modeling with confidential internal structure.

- Easier data sharing between component makers and OEM designers.

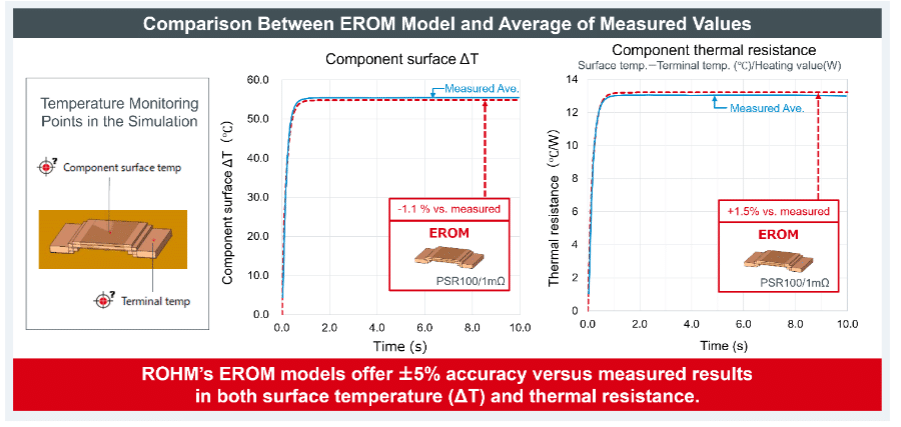

The strengthened EROM models claim measurement deviations within ±5% for both surface temperature (ΔT) and thermal resistance—figures that matter to thermal engineers who routinely juggle complex heat paths, multilayer PCB interactions, and package-level thermal bottlenecks. Higher predictive accuracy at the simulation stage typically translates to fewer prototype iterations and tighter design margins, saving both development time and system cost.

A notable aspect of the updated models is their ability to share thermal intelligence between component makers and OEM design teams without exposing sensitive internal structures. Since EROM operates as a reduced-order model within Flotherm, designers can run high-speed, near-real simulations while proprietary component geometries remain concealed. This confidentiality-friendly data exchange is increasingly sought after in the EV, industrial automation and renewable-energy sectors, where multi-vendor collaboration is the norm but IP protection remains critical.

With the models now integrated natively into Simcenter Flotherm 2510 and above, engineers no longer need manual imports or vendor-side customization—cutting friction for teams adopting model-based thermal engineering workflows. As power density continues to rise across automotive inverters, industrial motor drives, and energy-storage electronics, high-fidelity simulation tools are becoming essential rather than optional. The company’s expanded EROM offering reflects a broader industry push toward more accurate, collaborative, and simulation-driven thermal design practices, especially in markets where reliability and certification timelines leave little room for thermal surprises.