New edge-wound inductors built with powdered iron cores offer stable performance up to +180 °C, soft saturation, and up to 30% higher current handling—boosting efficiency in EVs, hybrids, and high-power automotive systems.

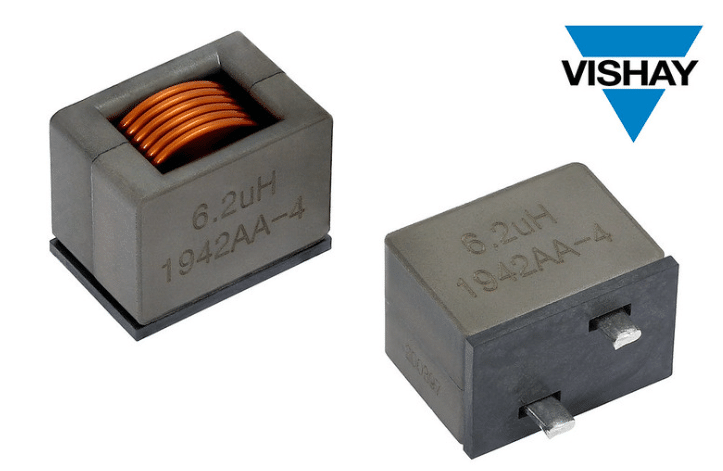

Vishay Intertechnology has launched two new power inductors that push the boundaries of automotive performance. The IHDM-1107BBEV-2A and IHDM-1107BBEV-3A—rugged, edge-wound, through-hole devices—are engineered to handle extreme temperatures up to +180 °C while maintaining stable inductance and soft saturation. Built with powdered iron alloy core technology, these inductors mark a significant upgrade over conventional ferrite-based solutions.

Designed in the compact 1107 case size, these Automotive Grade inductors offer an ultra-low DCR—down to just 0.22 mΩ—which helps minimize power losses and boost system efficiency. Their edge-wound coil design improves rated current handling, delivering up to 30% higher saturation and rated current levels at +125 °C compared to ferrite counterparts. The soft saturation ensures a predictable inductance roll-off as current increases, regardless of temperature—crucial for high-reliability automotive power electronics.

With high isolation ratings up to 350 V and full AEC-Q200 qualification, these inductors are tailored for demanding automotive environments. They’re ideal for use in DC/DC converters, inverters, on-board chargers (OBC), domain control units (DCU), and EMI filters in ICE, HEV, and EV platforms.

The IHDM-1107BBEV family comes in two performance-optimized variants:

- 2A: Inductance from 0.47 to 7.5 µH; saturation current up to 422 A

- 3A: Inductance from 0.68 to 12.0 µH; saturation current up to 248 A

Thermal performance is robust, with rated heat currents reaching up to 128 A. Surface-mount, press-fit, and bare copper terminal options are available on request, alongside custom configurations for inductance, DCR, and voltage rating. All models are RoHS-compliant, halogen-free, and Vishay Green, and feature hot-dipped tin plating to reduce whisker growth. Production quantities and samples are available now, with lead times of 14 weeks. In a sector that demands efficiency under pressure, the IHDM inductors combine thermal resilience, electrical stability, and customizability—ready to meet the growing power demands of electrified mobility.

For more information, click here.