Advanced machine learning model promises faster and more accurate estimation of wear-and-tear, in industrial systems.

A research team from the Indian Institute of Science (IISc) and Qatar Science and Technology Research Center (QSRTC) has created an AI-driven technique that can assess corrosion in industrial machinery in power generation systems without human intervention. The work was recently published in npj Materials Degradation.

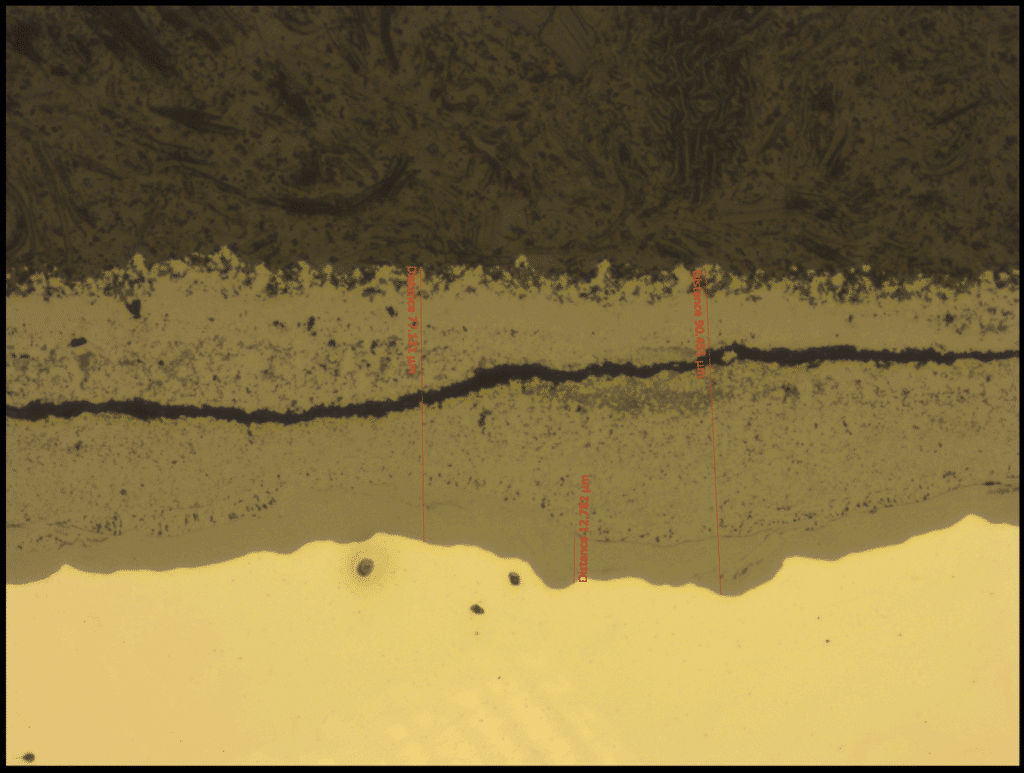

The system uses a machine learning algorithm to analyse microscope images of corroded metal surfaces. It estimates corrosion severity by examining two key features, thickness of the rust-like deposits and their porosity, or the number of tiny holes. These physical properties are linked to the concentration of corrosive substances and acidity beneath the deposits.

When corrosion advances, the deposits become thicker, with a corresponding increase in chloride levels and surface acidity. The team found that when the local pH drops below a threshold of 2.8 to 3, the corrosion reaches an advanced and damaging stage. This correlation between pH level and corrosion stage allows the model to serve as an early warning tool.

The algorithm was tested on steam generator tubes, which are prone to under-deposit corrosion in high-temperature industrial settings. It achieved 73% accuracy in identifying corrosion stages, significantly faster and more consistent than manual image inspection.

Unlike most machine learning models, this system uses an unsupervised deep learning method-k-means clustering to segment microscopy images without needing labelled datasets or human-defined categories. This makes it ideal for analysing complex and variable corrosion structures.

The model can be adapted to different corrosion types but will require fine-tuning for each case. The researchers aim to validate it further with larger, more diverse datasets. This AI-based method holds potential to improve safety, reduce maintenance costs, and accelerate the digital transformation of industrial monitoring systems.