A new system called LightLink uses visible light to let developers add sensors, actuators, and modules to commercial smartwatches—no firmware access or manufacturer support required.

Smartwatches may soon become far more customizable, thanks to a novel system that lets developers attach new sensors and modules without manufacturer support. Researchers at the University of Calgary have unveiled LightLink, a platform that uses visible light to transfer data between commercial smartwatches and external add-ons—sidestepping the usual hurdles of Bluetooth, Wi-Fi, or proprietary firmware.

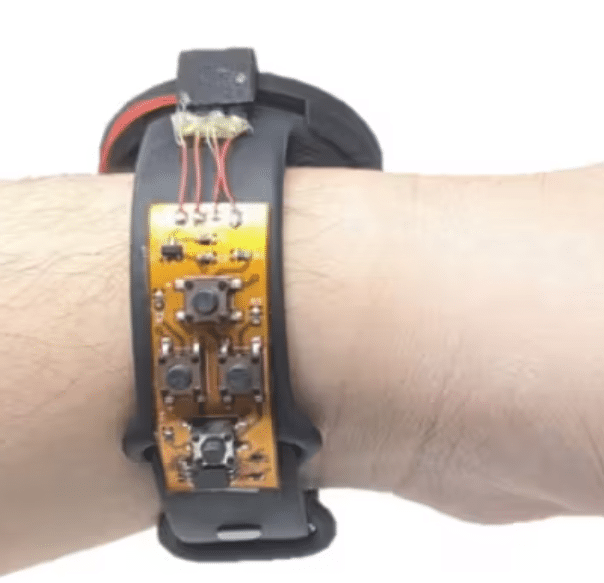

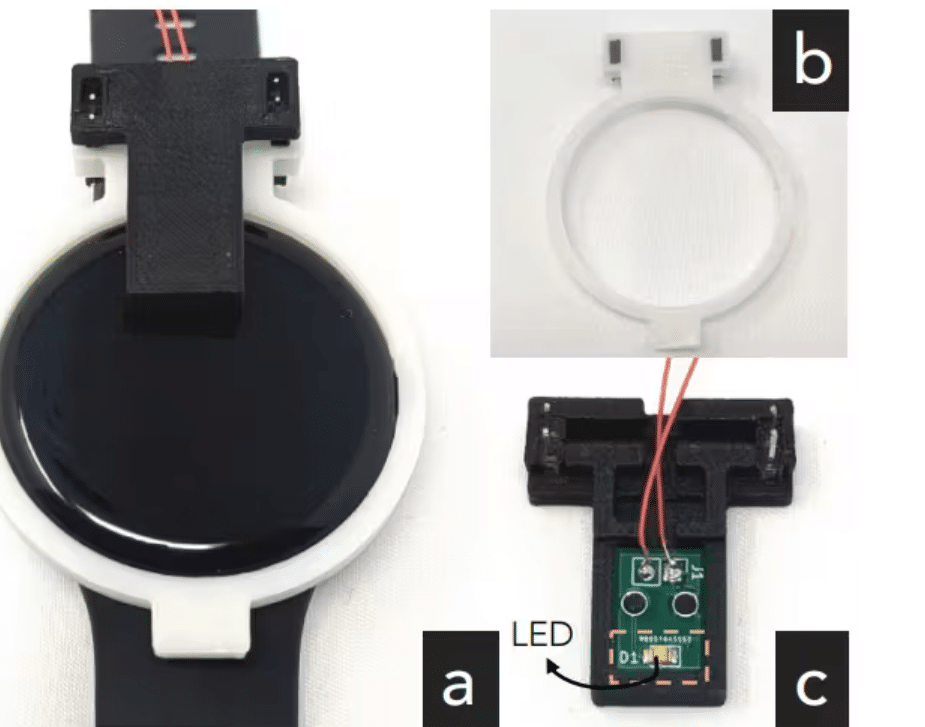

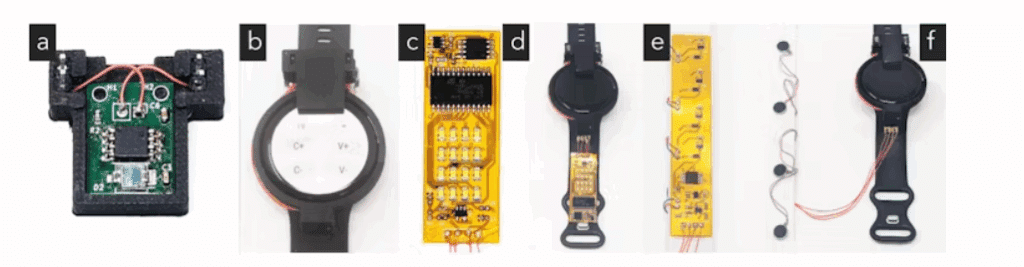

At its core, LightLink exploits hardware already standard in most wearables: the display and the ambient light sensor. By treating the watch’s screen as a transmitter and its light sensor as a receiver, the system enables two-way communication using flickers invisible to the human eye. Add-on devices, meanwhile, employ simple components—LEDs and photodiodes—to exchange data.

This setup allows external modules to seamlessly expand a smartwatch’s capabilities. For example, a thermometer can modulate an LED’s brightness based on its readings, which the watch then interprets as real-time temperature data. In the opposite direction, the smartwatch can flash patterns on part of its display, which a photodiode-equipped add-on interprets as commands. The result is bidirectional data transfer without firmware hacks or custom manufacturer APIs.

To prove the concept, the team demonstrated eight different add-ons ranging from basic buttons and environmental sensors to advanced modules like infrared transmitters and haptic wristbands. All functioned reliably across existing smartwatch platforms, showing that LightLink is device-agnostic and adaptable.The implications stretch beyond hobbyists. While the system was designed with DIY makers in mind—those who often build custom hardware because commercial options fall short—it could also inspire a new ecosystem of low-cost, light-based accessories. Instead of replacing an entire smartwatch for a missing feature, users could simply snap on a compatible module.

For developers and tinkerers, LightLink reframes the smartwatch not as a closed consumer gadget but as a flexible platform ready for experimentation. It also keeps projects from languishing in the “spare parts bin” by making it easier to merge polished commercial products with the creativity of homemade electronics.

In essence, LightLink shines a new light—literally—on what smartwatches can be: customizable hubs that grow with their users’ needs.