- The device’s system integrator along with its rich measurement features make it suitable for industrial applications as well

- Its low power consumption makes it more power-efficient than alternative Hall effect sensors

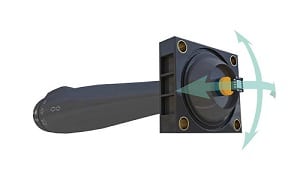

Melexis, a provider of micro-electronic solutions has launched the MLX90395 Triaxis Magnetometer Node, a monolithic sensor that uses the Hall effect for contactless 3D sensing. The MLX90395 meets the needs of demanding scenarios, such as gear lever position sensing in automotive applications.

Melexis, a provider of micro-electronic solutions has launched the MLX90395 Triaxis Magnetometer Node, a monolithic sensor that uses the Hall effect for contactless 3D sensing. The MLX90395 meets the needs of demanding scenarios, such as gear lever position sensing in automotive applications.

The functionality of the MLX90395 takes place through the system processor. It offers both I2C and SPI interfaces, making it simple to integrate into an automotive or industrial control environment.

The sensing solution’s digital output provides 16-bit resolution for X, Y and Z magnetic field (Bx, By, Bz) measurements, thus enabling the host processor, DSP, microcontroller or digital signal controller to decode the absolute position of any magnet as it passes the sensor.

Power-efficient measurements

The MLX90395 also has an integrated temperature sensor and supply voltage monitor. It operates in one of three modes: single measurement, burst mode and wake-up on change mode. Users can select which magnetic field is to be measured and the frequency of measurement for further fine-tuning the sensor’s energy efficiency as well as the filtering and sampling time to optimise noise vs bandwidth.

The MLX90395 is smaller and more power-efficient than alternative Hall effect sensors,. This helps provide an industry-low power consumption, with an idle current of 1.4 μA and standby current of 2.4 μA, and supply current of 4 mA or less.

Integrated bus platforms

Operational modes can be defined and selected at runtime through the I2C or SPI interfaces, allowing multiple sensors to form part of a sensor cluster, controlled by a single microcontroller. The bus protocol (SPI or I2C) is also selectable, running at up to 10 MHz for SPI and 1 MHz for I2C. Each sensor is given a unique 48-bit ID number during the manufacturing process and contains additional free space to store customer traceability information.

“The MLX90395 represents a new way of sensing position for the automotive and industrial markets, one that can redefine the way a wide number of applications are designed in HMI, top column, center stack and body control,” commented Nick Czarnecki, Global Marketing Manager Position Sensors at Melexis. “Its strengths lie in its high sensitivity and versatility, coupled with its low power and small size. Manufacturers now have access to the very best 3D magnetic node sensing solution qualified to an automotive-grade.”

Both medium-field (50 mT) and high-field (120 mT) versions are available in three package options: SOIC-8, TSSOP-16 (dual-die for redundancy) and QFN-16 (with wettable flanks). All package options are qualified to automotive-grade (AEC-Q100) and cover the extended temperature range for -40 degrees Celsius to +125 degrees Celsius and are RoHS compliant.