Built using polymer waveguides embedded in silicone, the technology could transform robotics, prosthetics, and next-gen wearables by giving machines a tactile sense that rivals human touch.

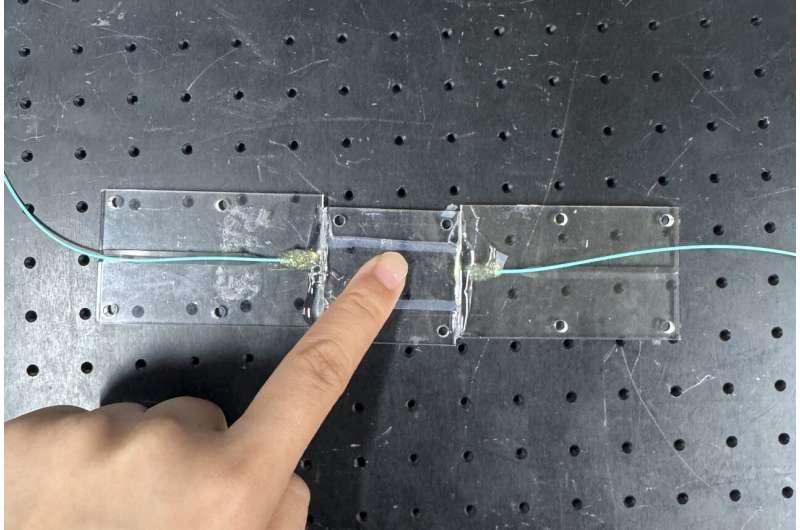

Researchers in Japan have unveiled a flexible optical touch sensor that can measure both the location and strength of pressure, marking a potential leap forward for robotics, prosthetics, and wearable electronics. Reported in Optics Express, the wafer-thin sensor achieves high sensitivity and stability, offering a tactile interface that mimics the nuanced sense of human touch.

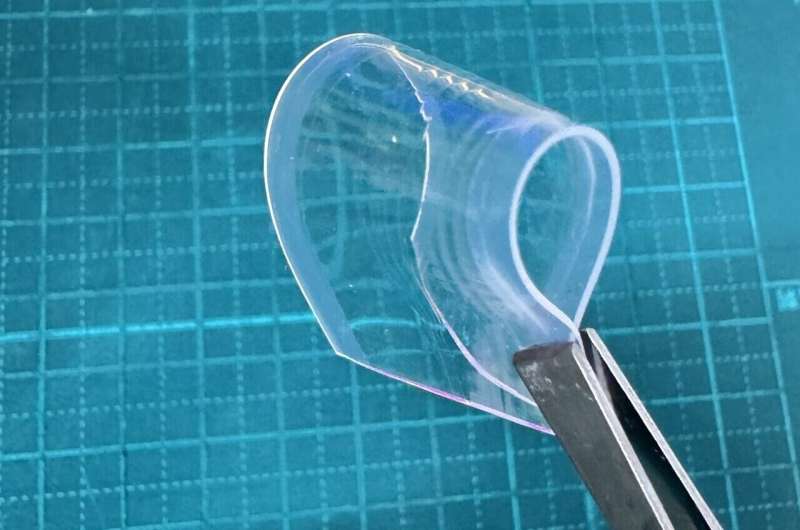

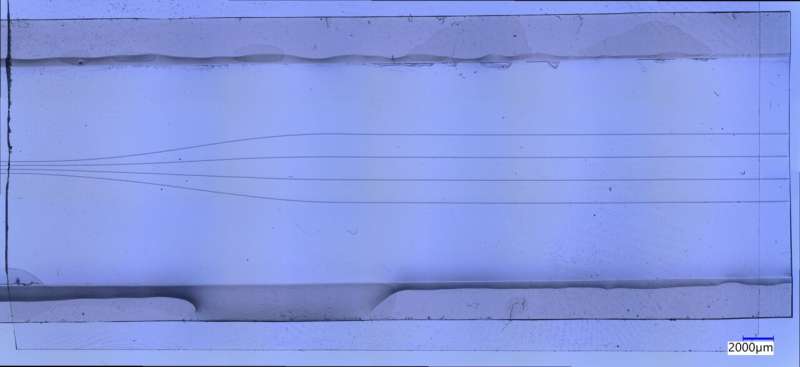

The device, developed by a team at Keio University, uses silicone rubber embedded with multiple polymer optical waveguides. Unlike conventional designs that rely on a single input-output path, this multi-channel approach enables the sensor to pinpoint pressure at several spots simultaneously. At just 500 microns thick and measuring 5 x 1.5 centimeters, the prototype demonstrated spatial resolution of about 1.5 mm—fine enough to detect fingertip-level pressure similar to tapping a smartphone screen.

The innovation hinges on the team’s Mosquito fabrication method, which uses a syringe to inject resin into a liquid polymer sheet before UV curing. This process allows 3D wiring of optical waveguides inside flexible PDMS (polydimethylsiloxane), creating thin light paths that bend when pressure is applied. The resulting changes in light intensity reveal both the force and position of the touch.

Tests showed the sensor reacting within 33 milliseconds, maintaining sensitivity between 8.7 and 10.9 dB/MPa, and proving resilient over repeated use. Unlike earlier designs embedding rigid glass fibers, this approach offers tunable sensitivity and greater design flexibility. The researchers envision expanding the technology to 3D cross-waveguide structures, improving resolution, and scaling it for larger, high-density tactile surfaces. Beyond robotics and prosthetics, potential applications range from surgical tools that sense tissue texture to wearable devices with real-time pressure feedback.

As tactile sensing becomes central to next-generation interfaces, this advance underscores a shift: machines may soon “feel” with unprecedented precision, blurring the line between artificial and human touch. “By creating multiple optical channels, we’re opening the door to scalable, highly adaptable tactile sensors,” said project lead Takaaki Ishigure. Such technology, he explained, could grant robots precision touch for safer human-robot collaboration, or provide prosthetic users with feedback closer to natural sensation.