A new rhodium-based material combines exceptional strength, elasticity, and conductivity to enhance probe pin performance and extend the life of semiconductor testing systems.

As semiconductor devices shrink and integrate more densely packed circuits, testing precision and reliability have become critical at the wafer level. To address the mechanical limits of existing probe pin materials, a new rhodium alloy—TK-SR—has been developed by TANAKA PRECIOUS METAL TECHNOLOGIES , to deliver an unprecedented balance of strength, elasticity, hardness, and conductivity.

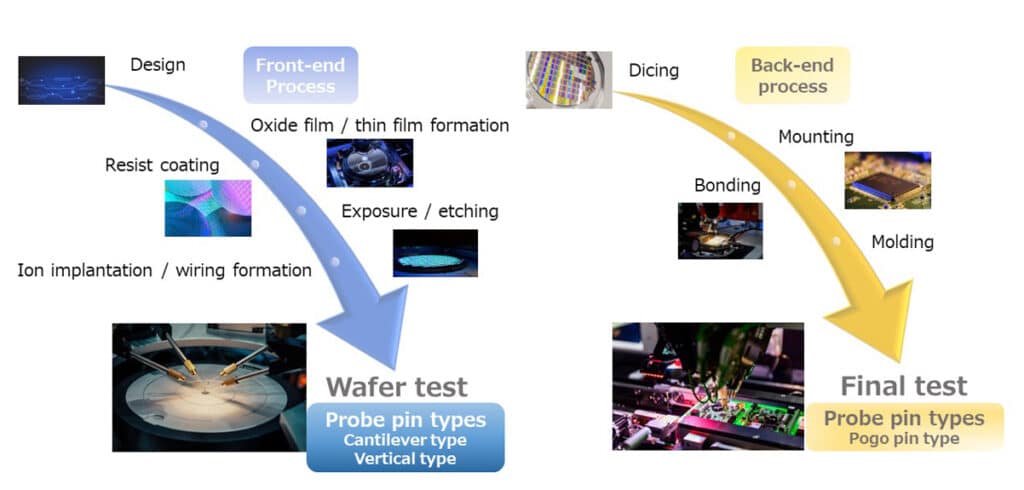

Probe pins, used in probe cards during front-end semiconductor testing, are subjected to repetitive micro-scale mechanical loads—often millions of cycles—while carrying test currents to wafer contacts. Even minor deformation or fatigue in a pin can lead to failure, resulting in costly downtime and replacement of probe cards. The TK-SR alloy directly targets this issue by significantly increasing the elastic limit and durability of rhodium wire, enabling consistent performance under extreme cyclic stress.

The key features are:

- High Strength & Elasticity

- Enhanced Hardness

- Ultra-Fine Wire Capability

- Next-Generation Material Processing

Developed using advanced material processing technology, this material can be drawn into ultra-fine wires as narrow as 18 micrometers. This level of precision supports testing of narrow-pitch, high-density semiconductor packages used across smartphones, data centers, and automotive electronics. By maintaining both mechanical stability and electrical conductivity, the material ensures lower contact resistance and improved reliability in repeated probing operations.

According to the company, its enhanced mechanical properties reduce deformation and breakage risk, helping extend probe card lifespan and lower total cost of ownership. Compared to conventional rhodium wire, it exhibits higher yield strength and stress tolerance—key factors for maintaining contact accuracy and reducing pin replacement frequency.

By 2030, the company aims to double the shipment volume of TK-SR compared to its current rhodium-based probe products, underscoring demand growth in semiconductor test infrastructure. Further information on the probe pin portfolio, including wire, plate, and plating solutions for semiconductor testing, is available by clicking here.