This enables consistent, cost-effective manufacturing of disordered rock-salt (DRX) cathodes—paving the way for more sustainable and affordable batteries for electric vehicles and renewable energy systems.

A global team led by researchers at McGill University has unlocked a breakthrough in lithium-ion battery technology—developing a cleaner, scalable way to replace nickel and cobalt with a more sustainable alternative: disordered rock-salt (DRX) cathodes. By refining how these materials are made, the team offers a real solution to the persistent cost and supply chain issues plaguing today’s battery production.

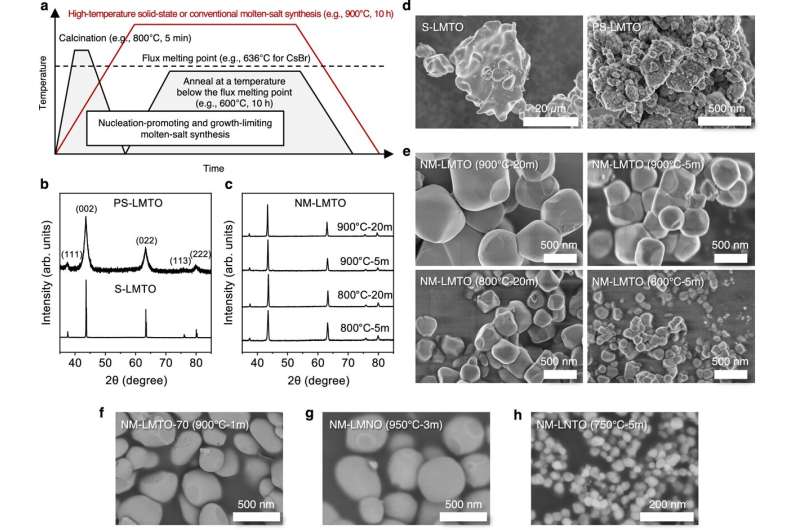

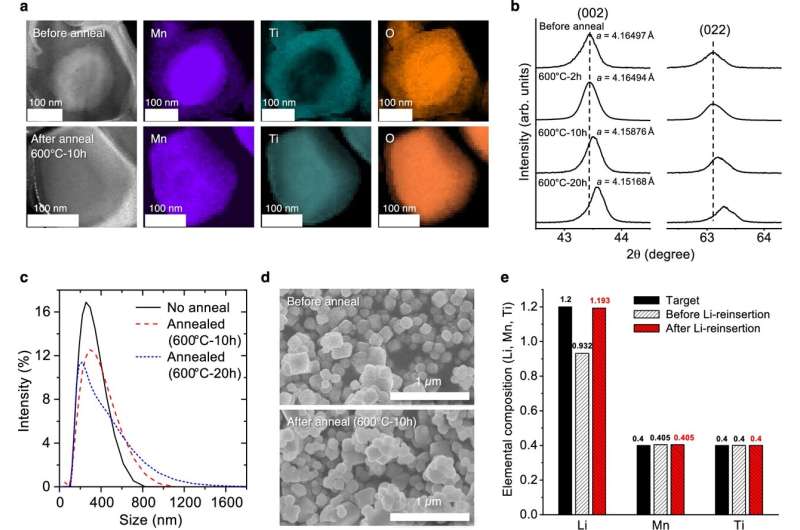

Traditional DRX materials were difficult to control and inconsistent in quality, making them unsuitable for mass production. The new two-step molten salt synthesis developed by the McGill-led team solves this by producing ultra-uniform, sub-200nm DRX particles with high crystallinity—without the need for post-processing like grinding. This not only improves the performance of the material but also makes industrial-scale manufacturing viable for the first time.

“Consistent quality is key for any battery material to succeed commercially,” said Prof. Jinhyuk Lee, the project’s corresponding author. “Our method makes it possible to mass-produce DRX cathodes with repeatable results and fewer processing steps.”

When tested in battery cells, these next-gen DRX materials retained 85% capacity after 100 charge cycles—over twice the retention rate of DRX made by older methods. That’s a big leap in energy storage efficiency. The method also eliminates dependence on expensive and ethically problematic metals like cobalt and nickel, lowering environmental and economic costs.

This materials science innovation was developed in collaboration with Stanford’s SLAC National Accelerator Laboratory, South Korea’s KAIST, and Wildcat Discovery Technologies—a battery company exploring commercial scale-up. Their findings, recently published in Nature Communications, show strong industrial potential for reshaping how lithium-ion batteries are manufactured.“By shifting the field toward scalable, energy-efficient synthesis, we’re opening the door to affordable, sustainable battery technologies that can meet global demand,” said lead author Hoda Ahmed. With this new approach, the path to next-gen lithium-ion batteries—cheaper, cleaner, and cobalt-free—just got much clearer.