A new confined crystallization approach is narrowing the efficiency gap between spray-coated and lab-scale perovskite devices, offering a scalable route to high-performance films on large, curved, and complex surfaces.

Researchers at the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) have developed a new “confined crystallization” strategy that substantially boosts the performance of spray-coated perovskite devices bringing them close to efficiencies traditionally achieved only with spin-coating methods. The work shows the approach yields cleaner crystal growth, lower defect densities, and scalable fabrication on complex surfaces.

Spray coating is a scalable, non-contact method well suited to large-area and three-dimensional substratesfrom building-integrated photovoltaics to curved optoelectronicsbut has historically lagged in efficiency due to uncontrolled crystallization and high defect densities in deposited films. Conventional solvents evaporate slowly and unevenly in droplets, creating impurities and disordered grain structures that degrade device performance.

The team’s confined crystallization approach restructures the crystallization pathway at the droplet level by engineering a localized high-concentration (LHC) precursor system. By adding weak ligand solvents, the method restricts the diffusion of key ionic components and improves their interaction with lead-iodide complexes. This suppresses unwanted intermediate phases and parasitic reactions, enabling homogeneous pre-nucleation and direct formation of highly oriented α-phase perovskite crystals as the film forms.

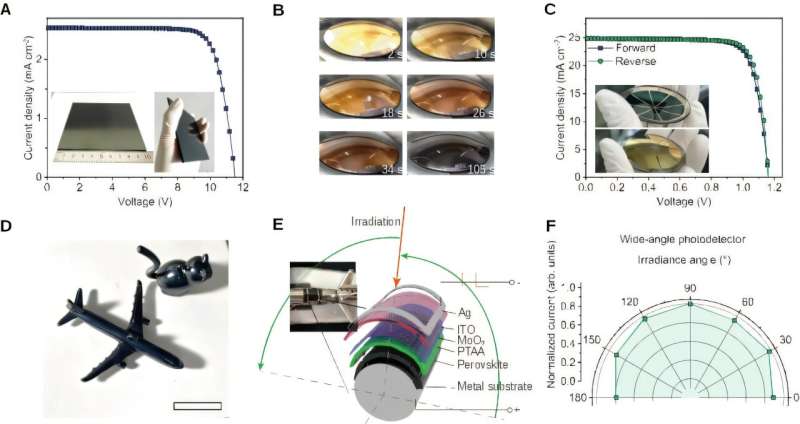

One of the major technical benefits of this strategy is a significant reduction in trap-state defect densitiesdown to roughly 10^14 cm⁻³producing films with far fewer electronic losses. Combined with machine learning optimizations, the team reported 25.5% power conversion efficiency (25.2% certified) for spray-coated perovskite solar cells, as well as mini-modules exceeding 22.5% efficiency. These figures approach those of state-of-the-art spin-coated cells.

Beyond high efficiency, the process tolerates higher humidity (around 80%) during fabrication and enables deposition on non-developable, curved substrates with performance above 23%, highlighting its potential for real-world, complex surface applications. Continuous thickness controlfrom nanometers to micrometersand compatibility with patterned and three-dimensional geometries further underscore the method’s versatility.

In summary, this confined crystallization strategy narrows the performance gap between scalable spray coating and precision lab techniques while expanding the manufacturing envelope for next-generation perovskite photovoltaics and optoelectronic devices.