MEMS sensor that combines ultra-wide pressure range with high precision in a chip 200x smaller than conventional systems—poised to disrupt semiconductor and aerospace technologies.

In a leap forward for vacuum pressure sensing, researchers at the Aerospace Information Research Institute (AIR), Chinese Academy of Sciences, have unveiled a novel dual-mode MEMS sensor that offers both high precision and an ultra-wide detection range—packaged in a chip smaller than a grain of rice. Led by Profs. Chen Deyong and Wang Junbo, the research appears in Microsystems & Nanoengineering.

Vacuum pressure sensors are essential for high-tech sectors like semiconductor fabrication, where tightly controlled environments are critical for processes like plasma etching and chemical vapor deposition. However, traditional sensors come with trade-offs: Pirani gauges offer wide range but low accuracy, while capacitance diaphragm gauges (CDGs) excel in precision but with a limited range. Hybrid solutions combining both are bulky, complex, and gas-sensitive.

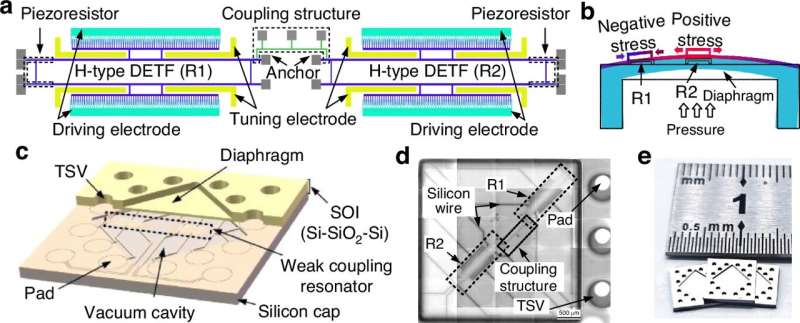

The team’s breakthrough: a MEMS-based sensor that merges both sensing modes into a single miniaturized chip, enabling continuous pressure detection across six orders of magnitude—from 0.3 Pa to 100,000 Pa. It intelligently switches between two modes: a mode-localization resonator mode for ultra-low pressures, and a conventional resonance mode for higher pressures.

This dual-mode integration achieves a remarkable resolution of 0.1 Pa in low-pressure environments and 2.0 Pa at high pressures. The sensor also boasts exceptional thermal stability, maintaining performance across –20°C to 120°C. Calibration error remains impressively low: just 1.99% at 120°C in low-pressure mode and as little as 0.01% of full scale under high pressure. Unlike many composite sensors, its performance is gas-type agnostic.

Perhaps most impressive is its size. With a volume of just 27.2 mm³, the MEMS sensor is over 200 times smaller than traditional composite sensors, simplifying integration into dense systems such as semiconductor process chambers or aerospace instruments.This sets a new benchmark for compact, high-precision, and wide-range vacuum pressure sensing. Its robust design and versatility position it as a game-changer for semiconductor manufacturing, aerospace engineering, and other precision-critical fields.