A new slime-like material could transform how lithium-ion batteries are made and recycled, promising faster charging and green manufacturing.

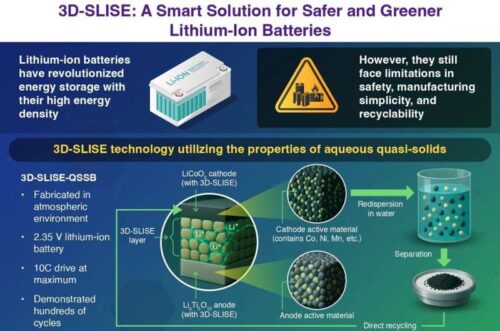

Institute of Science Tokyo researchers have developed a quasi-solid electrolyte, 3D-Slime Interface Quasi-Solid Electrolyte (SLISE), enabling safe, fast-charging lithium-ion batteries to be manufactured under ambient conditions without flammable organic solvents. The breakthrough allows 2.35 V batteries to be produced without dry rooms or high-temperature processing, while supporting direct recycling of active materials via water dispersal.

“Using this technology, it is possible to directly reclaim valuable elements like cobalt, contributing to a more sustainable and reliable supply of critical battery materials,” notes Yasui, Associate Professor. The team says 3D-SLISE offers a scalable, sustainable route to next-generation portable power electronics and clean energy storage solutions. It also unlocks the sustainable battery era and direct recycling. The research addresses safety, environmental, and cost challenges in current lithium-ion battery manufacturing, which typically relies on energy-intensive processes and hazardous solvents.

The technology uses a borate–water matrix to create a compact, slime-like electrolyte with 3D ion conduction, allowing lithium ions to move freely in all directions. Two slurry types were developed: Type E, for electrode fabrication, mixes with active materials such as lithium cobalt (III) oxide (LiCoO₂) for cathodes and lithium titanate (Li₄Ti₅O₁₂) for anodes; and Type S, used as the quasi-solid electrolyte layer between electrodes. Both are dried naturally at room temperature, suiting industrial-scale production.

When assembled like an all-solid-state battery, the 3D-SLISE-based cells maintained a voltage of 2.35 V at 1°C. It achieved over 400 charge/discharge cycles at 3°C under standard room conditions, supporting full charge or discharge in approximately 20 minutes.

Ionic conductivity reached 2.5 mS/cm with a low activation energy of 0.25 eV, enabling efficient operation at around room temperature. The electrolyte was produced by blending amorphous lithium tetraborate (a-Li₂B₄O₇) with lithium salt (LiFSI), carboxymethyl cellulose, and water. The resulting material forms self-supporting sheets on polyethylene terephthalate (PET) film, which dissolve instantly when stirred in water, simplifying recycling. Details are published in the Advanced Materials journal.