An automated system that weaves ultra-thin “fabric muscles” capable of powering wearable robots like everyday clothing—lightweight, flexible, and ready for mass production.

In a major leap toward clothing-like wearable robots, scientists at Korea’s Institute of Machinery and Materials (KIMM) have unveiled an automated weaving system that continuously produces “fabric muscles” made from shape memory alloy (SMA) yarns thinner than a human hair. This breakthrough paves the way for large-scale manufacturing of soft, lightweight robotic wearables that can assist multiple joints at once—without bulky motors or noisy pneumatics.

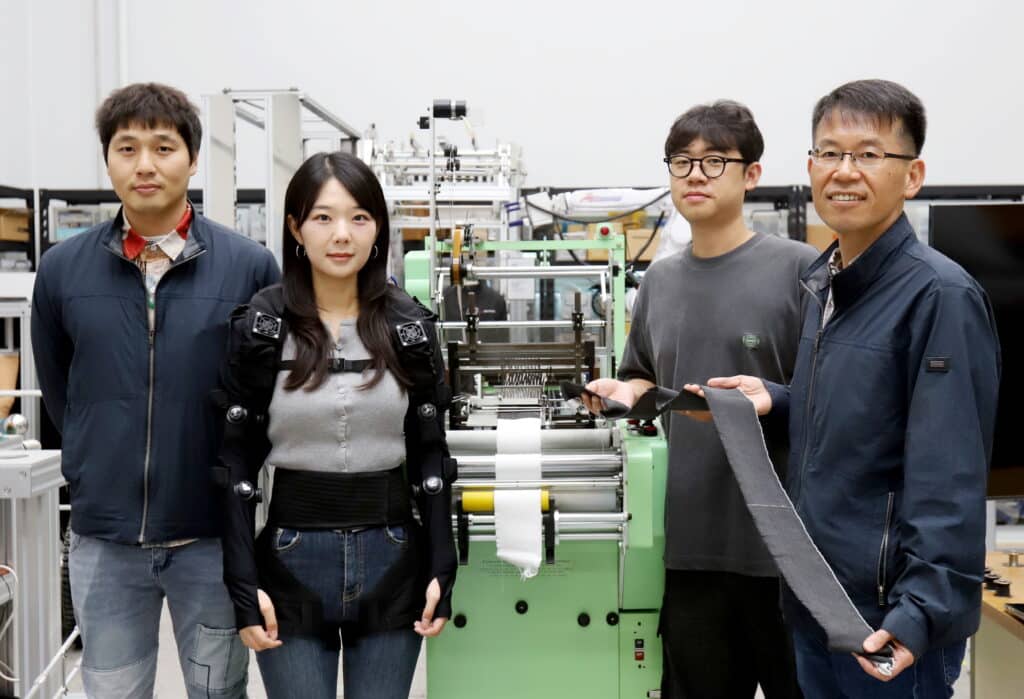

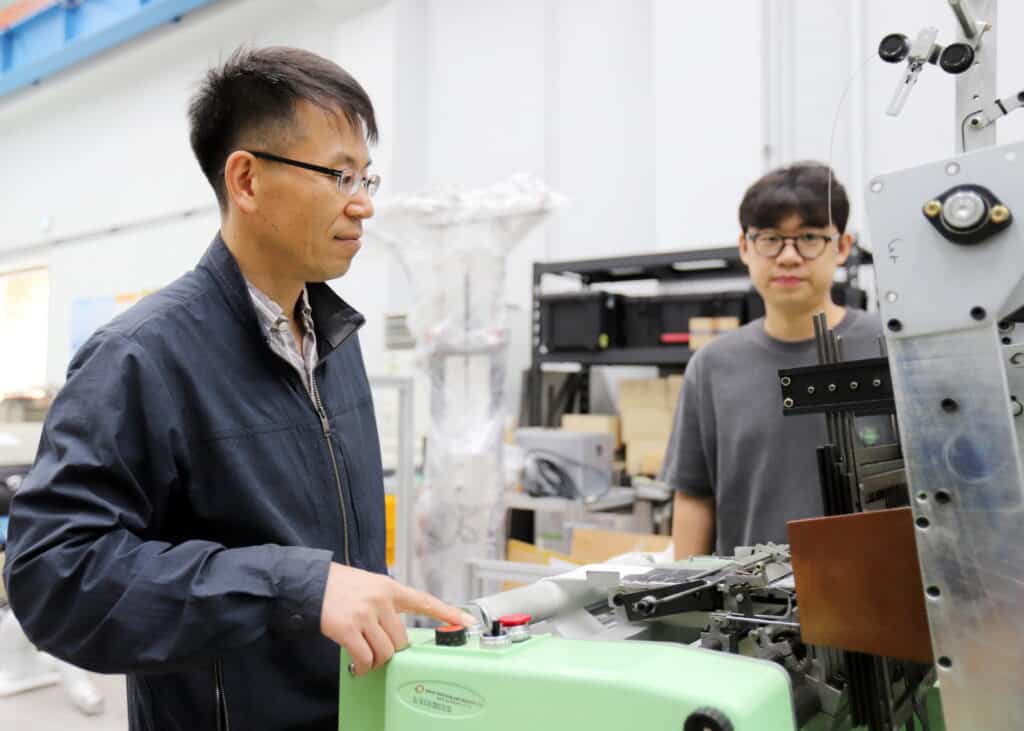

The KIMM team, led by principal researcher Dr. Cheol Hoon Park, engineered a process that converts 25-micrometer SMA wire into coiled yarn, then weaves it into high-strength textile actuators. Just 10 grams of this fabric can lift up to 15 kilograms—an extraordinary power-to-weight ratio that redefines how artificial muscles can function in wearable robotics.

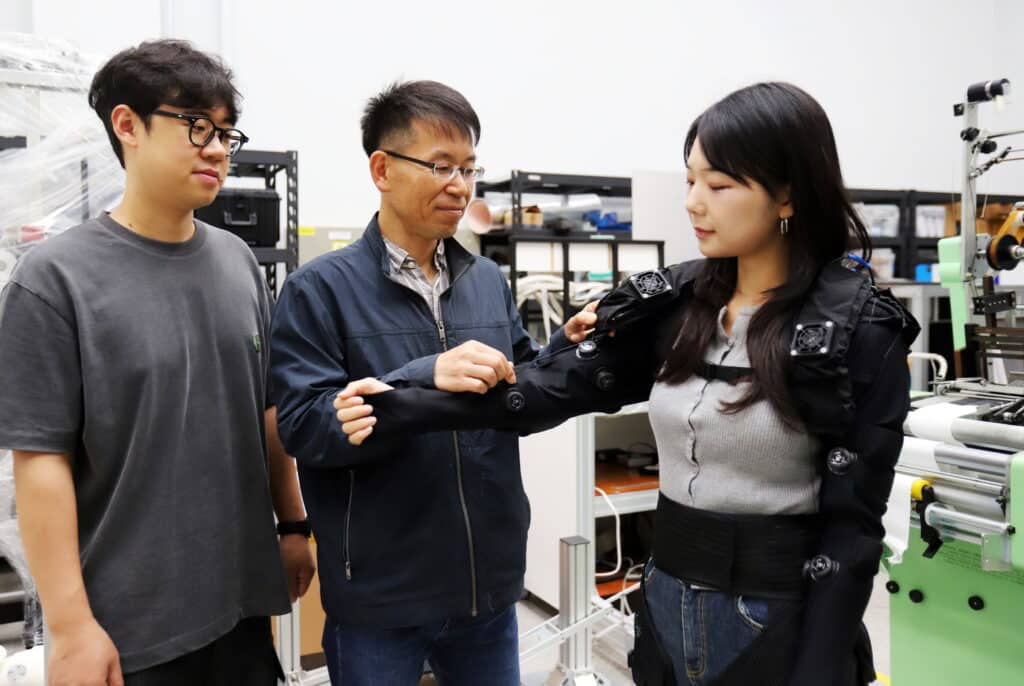

By replacing traditional metallic cores with natural fiber, the team overcame key limitations in flexibility and weaving precision. The redesigned coils and improved weaving machine allow stable, automated production—a critical step toward commercialization.Unlike conventional exosuits that typically assist only one joint, the new fabric muscle robot supports the shoulder, elbow, and waist simultaneously—all while weighing under 2 kilograms.

Tests show it reduces muscle effort by more than 40% during repetitive work. Another version, an ultra-light shoulder-assist model weighing just 840 grams, was successfully tested at Seoul National University Hospital, where it improved shoulder mobility in muscular dystrophy patients by over 57%.Beyond medical rehabilitation, the innovation could transform industries like logistics and construction by reducing worker fatigue. Its potential to enhance patient independence and ease caregiver burdens adds strong social and economic value.The study marks a pivotal stride toward commercial wearable robotics.

“This continuous production technology for fabric muscle is a turning point,” said Dr. Park. “It brings us closer to wearable robots that move as naturally as clothing.”