Intelliconnect has introduced high density multi-way connectors that can improve and simplify quantum processor operations.

Quantum computers are used to solve complex mathematical models. The computer works on quantum bits or qubits and hence is 158 million times faster than the most sophisticated supercomputer present in the world. The problem with these computers is that qubits are sensitive to several environmental factors like temperature and even disruptions to any part of the composite system.

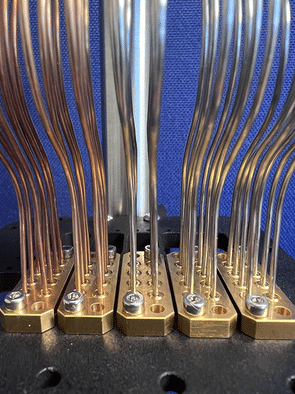

To tackle such issues, Intelliconnect has developed high-density multi-way connectors that improves and simplifies the architecture of quantum computers. These connectors are available in standard configurations such as 8-way, 16-way, and 24-way with either smooth bore or full detent options. They not only allow many more coaxial lines in a given space but also simplify the installation and customization within a dilution refrigerator (DR), a system used to operate quantum processors at temperatures near absolute zero.

CryoCoax, a division of Intelliconnect, has developed high-density multiway connectors based around the SMPM interface, which not only allow many more coaxial lines in a given space but also simplify the installation and customization within a dilution refrigerator. Typical spacing using SMA connectors is limited to approximately 16mm, whereas these high-density connectors are designed with a pitch of 4.75mm. The SMPM interface provides a simple push to mate connection only requiring a hex key to tighten the two fasteners.

Quantum processors are required to operate at temperatures near absolute zero, this can be achieved using a dilution refrigerator (DR), reaching temperatures below 20mK at the lowest stage. Each cooling stage is separated by a bulkhead/heat-shield to minimize heat transfer. The cables are installed between each of these stages and connect via feedthrough connectors and must provide good thermalization. Thorough thermalization of cables, attenuators, and microwave components at the various temperature stages is not only important for reducing the heat load on the dilution refrigerator, but also for reducing thermal noise within the system.

The company was able to prove the low-temperature reliability of the design over a number of thermal cycles, this was followed by in-house durability testing to confirm that the RF performance and DC resistance remained stable after multiple mating cycles.