Lyra, a robot, was employed to investigate a ventilation duct and map radioactive elements in a redundant nuclear laboratory in Dounreay (UK)!

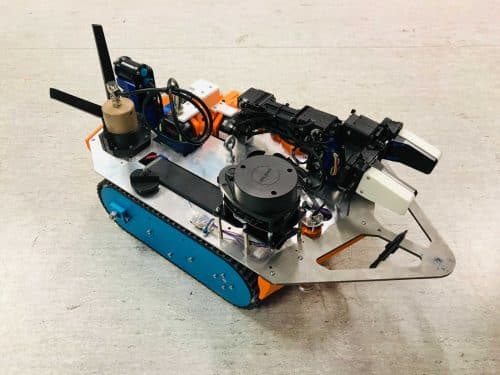

Lyra was built as a low-cost robot with five radiation detectors, a laser scanner for location, two cameras, lights, and a manipulator arm for swabbing radioactive pollution from the duct’s wall or floor. Lyra was created by researchers at The University of Manchester as part of the Robotics and Artificial Intelligence for Nuclear (RAIN) Hub, with help from Dounreay Site Remediation Ltd’s (DSRL) technical and operations professionals.

Lyra was equipped with tracks and given a reasonably high ground clearance. The radiation sensor package was built o measure beta, gamma, x-ray, and neutron radiations, and it included a 5 DOF manipulator for collecting swabs for further radiological examination at the site laboratories. Lyra’s front and the manipulator’s end were both fitted with cameras. The camera enabled a thorough examination of any areas of interest discovered during the survey. Lyra is controlled via a joypad for driving and a supple manipulator arm whose motion is replicated by the robot’s arm.

The radiation sensing package, in combination with the LIDAR radar and live camera footage, allowed for the creation of a 3D, time stamped video with the measured radiation readings overlayed onto the video.

“We wanted to demonstrate that the robot could be used successfully in active areas. We added fail safe devices, including a remote “reboot” switch, and a winch to enable us to physically retrieve the robot if it got stuck on the debris in the duct. The survey has demonstrated Lyra’s reliability in active areas”, says Barry Lennox, RAIN Director.

Following the successful deployment of Lyra, DSRL Project Manager Jason Simpson said, “DSRL is greatly indebted to the team from The University of Manchester, their efforts coupled with that of FIS360 Managing Director Frank Allison have clearly demonstrated the substantial benefits to be gained through collaborative working with the supply chain. Now that the characterisation survey is complete, we have built up a comprehensive picture of the duct which will help us make informed decisions on how the duct will be decommissioned going forward”.