Once a non-rechargeable battery, zinc-air battery tweaked to become rechargeable one and records higher charge and discharge cycles.

Development of new rechargeable Zinc-air battery records 3570 charge cycles over 74 continuous days of testing. The work replaces platinum and ruthenium catalysts with cobalt-doped carbon sheets, lowering costs while extending battery life.

Zinc-air batteries are metal-air electrochemical cells, generating energy from the reaction between zinc and oxygen. Known for high energy density material. The challenge has been that zinc-air batteries are non-rechargeable. and rechargeable designs face low power output and poor stability during repeated cycling.

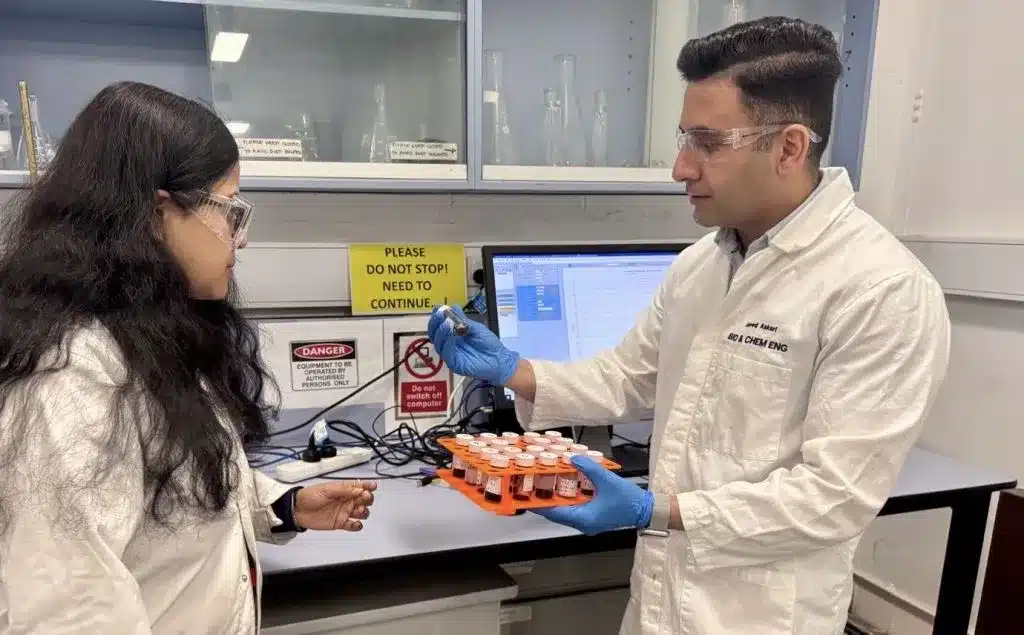

Researchers at Monash University in Australia address this issue by applying heat treatment to transform 3D material into thin carbon sheets. In this framework, cobalt and iron atoms are introduced at the atomic level. This design produces a catalyst capable of improving charge transfer and reaction rates inside the cell.

As a result the scientists made a zinc-air battery a rechargeable one, that operates continuously for more than two months, withstanding thousands of charge and discharge cycles. This device shows a power density of 229.6 milliwatts per square centimeter and energy density of 997 watt and hour per kilogram. By comparison, commercial lithium-ion batteries typically achieve 150 to 250 watt-hours per kilogram, exceeding the limits of commercially available batteries.

The research takes place in the Department of Chemical and Biological Engineering.The approach also has wider applications in fuel cells, water-splitting systems and carbon dioxide conversion, where stable and efficient catalysts are required.