Why does India hold such significance for Nichicon’s capacitor division? What drives the company’s optimism about its SLBs and film capacitors, and how is it preparing to tap India’s full potential?

As India’s electronics manufacturing sector expands rapidly, particularly in automation, power grids, and the EV sector, explore the vast market for passive components like capacitors and batteries with Nichicon in the energy storage segment.

India: A Key Growth Market

Headquartered in Kyoto, Nichicon has long been recognised for its expertise in Aluminium electrolytic capacitors, and film capacitors. We have been active in India since 2012, with offices in Bengaluru, Delhi, and Pune supporting a growing base of local customers.

The Indian market holds strategic importance for us, driven by its vast population and rapidly advancing electronics and automotive industries. As the world’s largest producer of two-wheelers and the third in four-wheelers, India requires high-performance capacitors suited for EV two-wheelers, smart meters, and solar devices, segments that directly fuel our capacitor business growth.

How Indian engineers play a role in the global design chain

The ecosystem for Indian engineers operates through a distributed design process across multiple countries. For instance, an application engineer in Europe may develop a product first, followed by a components engineer in India validating the components, and a procurement manager in Asia selecting the supplier. This international division of labour is becoming increasingly popular due to India’s strong technological talent pool. Global companies are now establishing R&D functions in India and outsourcing parts of their design processes. This ‘design win’ activity in India contributes significantly to global orders.

The Make in India and Design in India policies have opened tremendous opportunities for us. India’s unique strength lies in completing the entire cycle, from design conception to mass production, within the country. This enables us to engage with engineers during the crucial design phase, ensuring our components are selected early and carried through to full-scale manufacturing. We are capturing this opportunity by providing continuous support throughout the journey, from initial component validation through to production ramp-up.

With India’s ability to handle the complete cycle from design to mass production, we collaborate closely with local engineers during the design phase to ensure our components are integrated early and maintained through manufacturing. Our continuous technical support strengthens these partnerships from validation to large-scale rollout.

Solutions for modern electronics

We focus on developing custom capacitor line-ups tailored to Indian applications such as EVs and smart electronics. By understanding local demands, we create products that meet specific performance needs. For instance, capacitors for EVs must withstand vibration and deliver high ripple current, while those for smart meters require reliable backup power under India’s wide temperature fluctuations.

India’s EV and smart meter manufacturers face a critical challenge: conventional batteries cannot handle 50°C temperatures and daily cycling. At the same time, traditional film capacitors have two-to-three-year lead times that stall product launches. Our SH / EM series modular capacitors address these challenges effectively.

Since establishing a local presence, Nichicon has expanded beyond aluminium electrolytic capacitors into film capacitors and small lithium-ion rechargeable batteries known as SLBs. Our sales team continues to grow steadily to provide better technical support.

Product overview

The products showcased at the event

- SLB battery series

- SH / EM series capacitors

These two products target distinct market segments.

Small lithium-ion rechargeable batteries (SLB) are developed for IoT devices, wearables, and energy harvesting applications because of their high energy density characteristics. The SH / EM series capacitors, on the other hand, are specifically designed for EVs because of their compact and modular design, unlike the large, bulky aluminium electrolytic capacitors.

Small Lithium Titanate Rechargeable Batteries (SLBs)

Core features:

- The SLB series offers exceptional cycle life. After 25,000 charge/discharge cycles, it retains 80% capacity and, in testing, reaches up to 35,000 cycles, far exceeding the lifespan of conventional lithium-ion batteries.

- In just three minutes, the battery charges to approximately 80% capacity.

- It operates smoothly across a wide temperature range from -30°C to +60°C, with high-temperature models available up to +80°C, maintaining over 50% capacity even at temperature extremes.

- Low internal resistance: It enables efficient power delivery with minimal voltage drops, as low as 0.6Ω at 1kHz.

The batteries comply with UN38.3 transport standards and exhibit extremely low risk of fire or smoke, even when subjected to short circuits, crushing, or nail penetration tests. From a maintenance perspective, the 25,000+ cycle life means these batteries rarely need replacement, reducing long-term costs—especially in remote installations where servicing is difficult.

Fully charged, the SLB can deliver backup power for three to four minutes, far longer than competing technologies of similar size. With higher energy density and exceptional durability,

Our SLBs are ideal for compact electronics such as the Samsung Galaxy S Pen, enabling reliable remote sensor functionality.

Note: If you require an evaluation board to test different applications, Nichicon provides one, and our Field Application Engineer will contact you.

For More details, click the link here

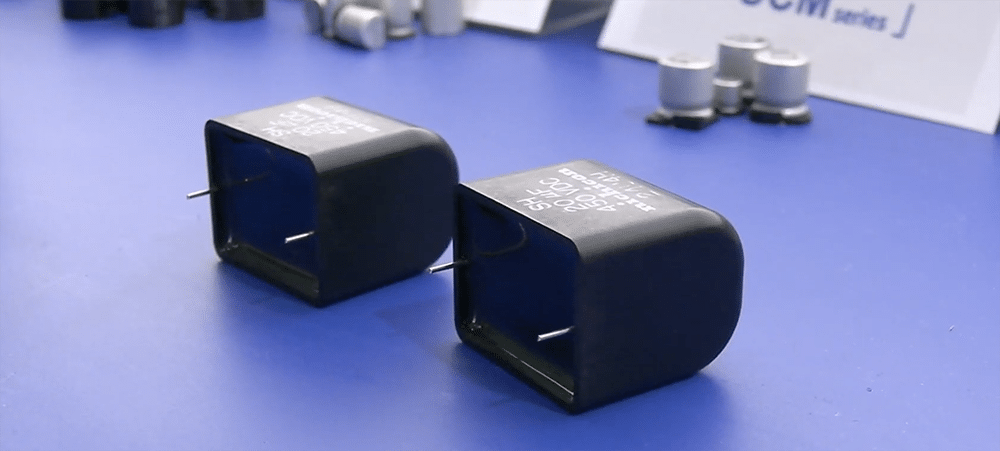

SH / EM series capacitors

In India, the EV segment is currently growing very rapidly. As a capacitor manufacturer, we may be part of the passive component industry, yet we are internally developing advanced products to meet evolving needs. The EV trend increasingly demands very high capacity, high ripple current, and compact case sizes.

Key features:

- This series capacitor offers a modular design; multiple units can be connected in series or parallel to achieve 3,300µF capacitance and 10A ripple current performance.

- Our SH / EM series capacitor design is compact and cost-effective, yet it performs like large capacitors, delivering up to 1000V high-voltage performance in smaller footprints and at a lower cost than bulky film capacitors.

- It is AEC-Q200 automotive qualified and meets automotive standards for 10G vibration resistance and -25°C to +70°C temperature range.

Instead of using large single film capacitors, we provide smaller aluminium electrolytic capacitors. Customers can use multiple cylindrical components in series or parallel to achieve the same performance, offering modularity, flexibility, and faster production and procurement.

We plan to begin mass production in 2026. Samples are already available and are being supplied to select customers for testing. Full-scale availability will commence in 2026.

For more information about the product, click this link.