While AI reshapes energy storage, human innovation remains central, intelligent batteries, machine learning, and smart energy systems combine to enable a cleaner, more reliable, and smarter future.

AI is transforming how we anticipate battery performance and prevent failures. Digital twins and prognostic models deliver detailed insights into a battery’s behaviour and lifespan, and machine learning improves prediction and reliability through pattern analysis. Combined, these approaches underpin smarter, more resilient battery systems.

What is a digital twin in battery systems?

A digital twin is often misconstrued as a physical copy or a backup mechanism. In battery energy storage systems (BESS), however, it is a cloud-based virtual representation of the physical asset’s behaviour, enabling performance analysis and prediction without hardware interaction.

Why does battery energy storage matter today?

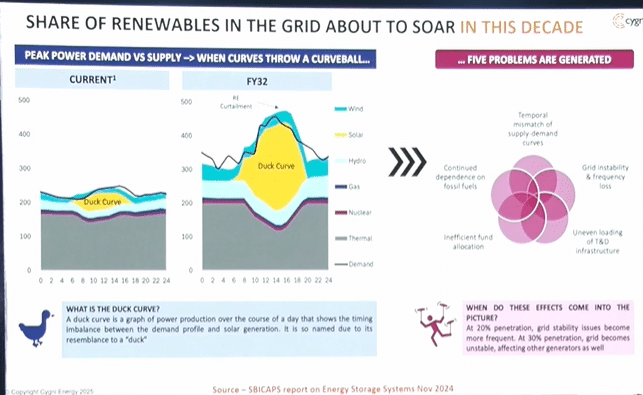

The growing adoption of renewable energy has made battery storage increasingly essential. Several Indian states have surpassed 20% renewable energy uptake, with Maharashtra and Karnataka approaching 30% and 40%, respectively. While this is a positive development, renewable energy sources are intermittent, creating challenges for grid operations.

Solar and wind generation do not match demand, so the famous duck curve occurs, which is the highest supply when demand is low, and vice versa. The outcome is reduced clean energy, rapid growth in thermal plants, uneven load on the transmission system, and an increasing risk of grid instability, as seen worldwide. In the event of persistent mismatches, the use of fossil fuels resurfaces, nullifying net-zero goals. This preconditions a definite question of the energy transition. What is the answer to the question of how to close the discrepancy between clean energy supply and dependable demand?

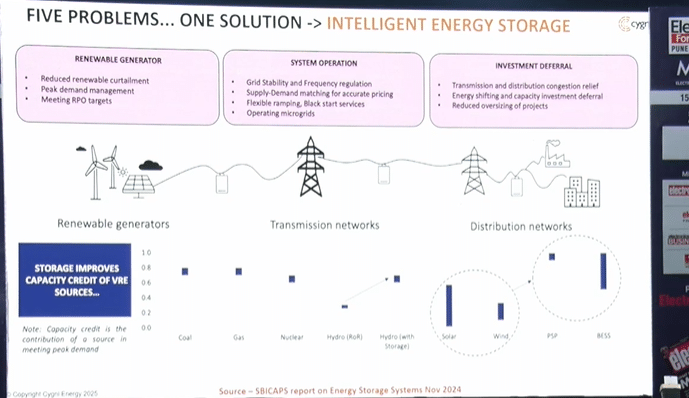

Storage: A single solution to multiple problems

Smart grid energy storage will provide an efficient answer to the problems of integrating renewable energy. This can be achieved by storing renewable generation in batteries, eliminating curtailment, and dispatching clean energy as needed. Storage can defer expensive investments in new transmission lines for transmission operators and can be used at the front or back of the meter to enhance distribution operator reliability.

This is evident in India’s large-scale storage tenders ranging from 500 to 1000 megawatt-hours. Storage also addresses the issue of solar energy’s capacity credit. Although solar cannot be dispatched on demand, combining it with storage makes it more reliable and valuable. Energy storage reduces multiple grid challenges to a single, scalable solution.

Why storage adoption has accelerated

Lithium-ion batteries are not new, but their economics have shifted dramatically. Around 2010, storage costs were nearly $1000 per kilowatt-hour, making large-scale adoption impractical. Today, prices have fallen well below $100 per kilowatt-hour, a fraction of their previous cost.

This cost decline has propelled energy storage beyond a long-anticipated inflection point, triggering rapid adoption. With millions of electric vehicles expected and large-scale stationary storage deployments underway, the growth trajectory of battery storage is set to be transformative.

What do we do at Cygni?

At Cygni, we focus exclusively on BESS. Operating downstream of cell manufacturing, we design, engineer, and integrate storage solutions for a range of applications. Supported by robust R&D and engineering capabilities, we manage projects across sectors and operate 4.8GWh of manufacturing capacity.

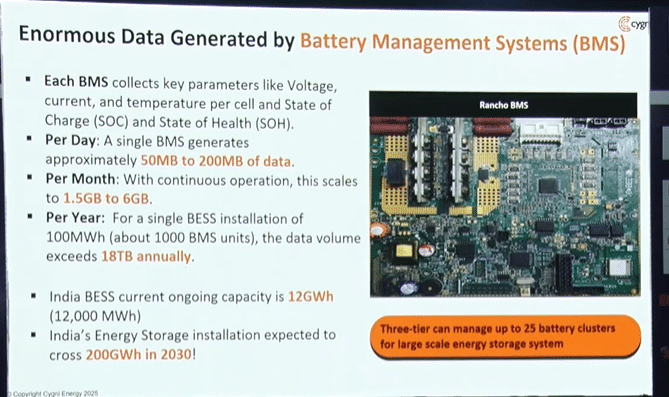

Battery management systems and the data explosion

Battery management systems (BMS) sit at the core of modern energy storage. Each BMS uses advanced microcontrollers and analogue front ends to monitor voltage, current, temperature, and other critical parameters, while calculating state of charge, state of health, and related metrics. A single BMS can generate 50 to 200MB of data per day, and with multiple BMS units in every electric vehicle and energy storage installation, volumes scale rapidly.

A single system can produce up to several gigabytes of data each month, while a 100MWh storage installation can generate tens of terabytes annually. With India already deploying over 12GWh of storage and significantly more in the pipeline, data generation and growth will be exponential. Without intelligence, this data has little value. The real opportunity lies in transforming it into actionable insight.

From dumb batteries to predictive systems

Despite advances in BMS hardware, most batteries remain largely reactive, measuring data rather than anticipating outcomes. The next shift is toward prediction. Predicting safety events, remaining battery life, and maintenance needs based on real usage data enables new value creation, from usage-based insurance models to accurate asset lifecycle forecasting.

Achieving this requires two layers. At the edge, intelligent BMS hardware/software, powered by powerful microcontrollers, capture high-fidelity data. At the platform level, this data is aggregated and analysed using AI and machine learning. Together, they enable predictive maintenance, risk assessment, and new monetisation models, positioning machine learning as a central driver of the future battery ecosystem.

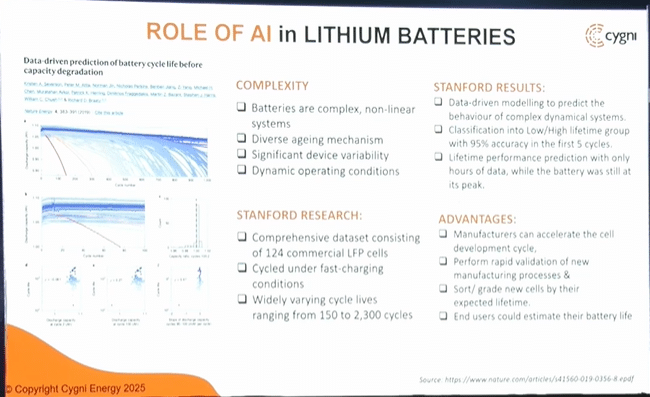

Predicting battery performance using AI research

Lithium-ion batteries are extremely complex, non-linear chemical systems whose behaviour changes with temperature, charging/discharging rate, and operating conditions. A Stanford seminal research paper demonstrated the power of data-driven prediction of battery cycle life by analysing gigabytes of data from lithium cell manufacturers and their products. The analysis using sophisticated models indicated that battery performance could be predicted within the first five cycles with over 95% accuracy, eliminating months of conventional testing.

This breakthrough changes how batteries are developed and deployed, accelerating chemical innovation, simplifying manufacturing validation, and improving the predictability of field analysis. With better models, the accuracy of predictions is likely to approach near-certainty, necessitating a fundamental rethinking of how battery reliability is defined and managed.

Energy management systems and the evolving grid

All battery systems rely on an energy management system (EMS) to coordinate batteries, renewable generation, and the grid, optimising load in real time. As India’s power system shifts from a static to a dynamic grid, the role of EMS is becoming mission-critical.

There is rapid development in forecasting, accountability, grid stability, and market trading mechanisms. Energy trading, day-ahead forecasting, and grid codes are evolving at an unprecedented pace. The grid of the future will be more decentralised, democratised, renewable-intense, and flexible.

Battery passport and ethical supply chains

Battery passports bring much-needed transparency to energy storage by digitally tracking batteries from raw material extraction to end use. By addressing ethical, safety, and sourcing concerns around critical minerals like cobalt, they can transform accountability across the battery value chain—earning the moniker “Battery Aadhaar” in India.

AI across the renewable energy ecosystem

AI is now deeply embedded across the energy ecosystem – from solar and wind forecasting to vibration analysis, smart inverter control, grid congestion management, and battery dispatch optimisation. Predictive dispatch enhances energy arbitrage while extending battery life, as smart meters, microgrids, and decentralised grids, along with reinforcement learning, redefine how power systems operate.

In this transition, data is the fuel and machine learning is the engine. Robust data infrastructure and AI-driven tools are no longer optional. They are essential to the future of energy.

A question on sodium-ion batteries

Sodium-ion batteries, built from earth-abundant materials, offer a strategic advantage by reducing reliance on imports. Their battery management systems exhibit unique characteristics, including a wider voltage window than LFP cells, safe transport at 0% state of charge, and superior low-temperature performance. Although heavier than lithium batteries, sodium-ion batteries unlock significant opportunities for innovation for targeted applications.

The article is based on the Pune Expo’25 session called ‘Empowering Energy: The Role of Electronics and AI in Revolutionising Battery Energy Storage Systems,’ featuring the opening speech by Venkat Rajaraman, Founder & CEO, Cygni Energy. It has been transcribed and curated by Vidushi Saxena, Journalist at EFY.