The power supply accounts for more than 90 per cent of the total electrical input to the system. The efficiency of this supply is therefore the prime determinant factor for the overall electrical efficiency of the laser. The conversion efficiency also directly affects the size and weight of the overall system, a parameter particularly important in the military applications of Q-switched, flash-lamp-pumped solid-state lasers.

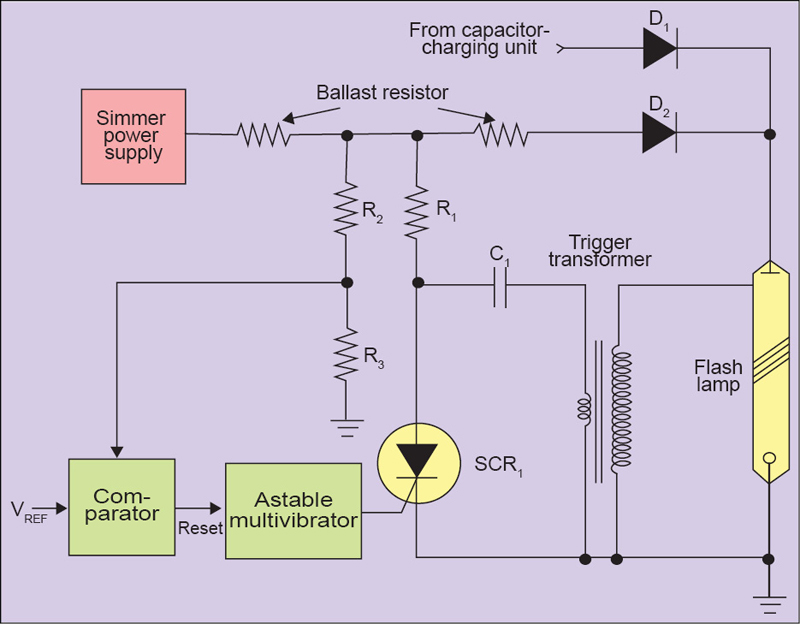

The simmer module maintains a relatively low-amplitude keep-alive current through the flash lamp at all times, irrespective of whether the lamp is flashing or not. The current varies typically from a few tens of milli-amperes to several hundreds of milli-amperes depending upon the characteristics of the flash lamp. This mode of operation, called the simmer mode, has many advantages.

From the operational viewpoint, it allows one to use a low-voltage (TTL and CMOS) trigger pulse to transfer the energy stored in the capacitor to the flash lamp. Besides, it significantly enhances the flash lamp life, offers tremendous improvement on the pulse-to-pulse jitter and overcomes most of the electromagnetic interference problems present in non-simmer mode of operation.

It may be mentioned here that in the non-simmer mode of operation of the flash lamp, the triggering of the flash lamp is done by applying high-voltage trigger pulses with amplitude of the order of 10kV to 15kV. These pulses appear at a rate equal to the repetition rate of the laser and are the major source of electromagnetic interference.

Operation in simmer mode overcomes this shortcoming. There is a pseudo simmer mode of operation also, which is a slight variation from the traditional simmer mode. In this mode, the simmer current flows for a short time, starting a little ahead of the energy discharge operation. It has all the advantages of simmer mode operation and in addition saves power, but at the expense of added circuit complexity.

Q-switch driver is another important module for solid-state lasers as it generates drive signal for electro-optic Q-switch. The driver needs to generate a high-voltage pulse having the desired amplitude (typically, 2.5kV to 3.5kV), pulse width that could be in the range of 200ns to 500ns and a rise time that should not be more than a few tens of nanoseconds.

The pulse-forming network (PFN) ensures that the discharge current pulse through the flash lamp has the desired pulse width and is critically damped, thus giving the most optimum energy transfer.

The command module generates flash lamp firing command pulses and also the delayed trigger pulses for the Q-switch driver module. It may be mentioned that Q-switch drive pulse is applied after a certain known time delay from the application of flash lamp trigger command pulse to allow for the population inversion to build up to its peak value.

The flash lamp command pulses in the case of simmer mode operation are low-voltage pulses (TTL and CMOS) and high-voltage trigger pulses in the case of non-simmer mode of operation. The delayed trigger pulses for the Q-switch driver are always low-voltage pulses and the Q-switch driver produces the desired high-voltage pulses for the electro-optic Q-switch. In addition, there is an auxiliary module that generates the regulated low-voltage DC power supplies from the input source of power for the operation of different circuit modules.

In the case of non-simmer mode of operation, electronics is similar to the one for simmer mode of operation, except that there are no electronic switch and simmer power supply and that the command module feeds a high-voltage trigger generator circuit.

Capacitor-charging power supply

The capacitor-charging power supply is the most important of all the modules for reasons outlined earlier. The power supply output needs to charge a high-value capacitor, typically 20µF to 50µF in case of designators and rangefinders and as high as thousands of microfarads in high-power pulsed lasers, producing laser pulse energies of several kilojoules meant for electro-optical countermeasures and laser weapon applications.

Switched-mode concept is invariably used for the design of capacitor-charging power supply. Externally driven flyback converter is the preferred topology. Its design, however, is not as straightforward as it would be in the case of a resistive load. The reason is as follows.

In the case of capacitive load, energy storage and energy transfer mechanisms are relatively more complex. Each time an energy packet is stored in the primary of the transformer and subsequently transferred to the capacitor, the time needed to transfer the packet of energy depends upon the quantum of voltage it would impart to the capacitor.