Small Modular Reactors (SMRs) have shifted from science fiction to ready science. To achieve clean, stable, scalable energy, it’s time to move beyond legacy reactors and invest in this compact revolution.

“The potential of SMRs is immense, providing scalable, secure, and environmentally responsible energy solutions that the world needs.” — International Energy Agency (IEA)

Table of Contents

Nuclear power is set to play a pivotal role in the clean energy transition, offering high-density, carbon-free, and reliable energy that complements the variability of renewables. Though not renewable, nuclear energy generates substantial power using minimal land and operates independently of weather conditions.

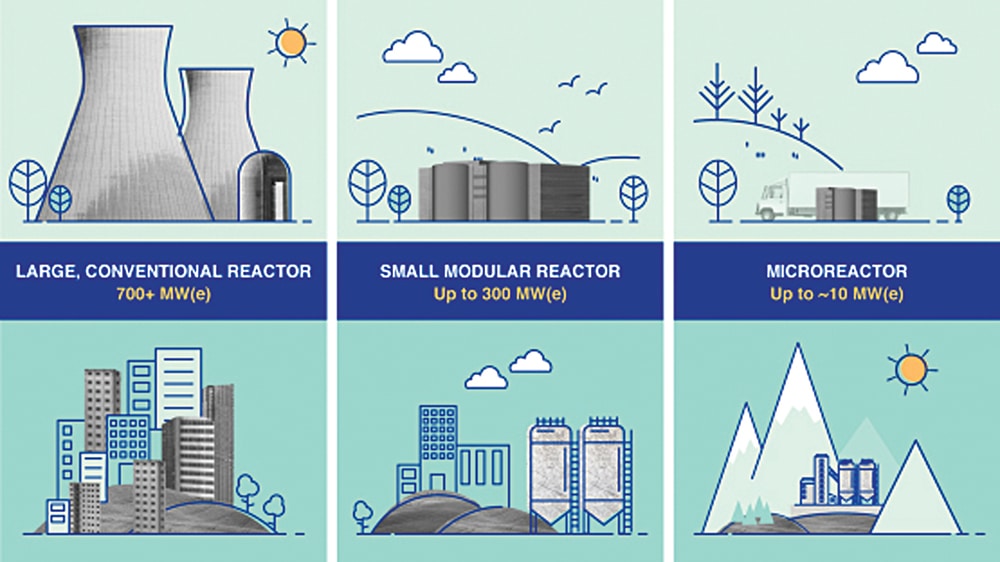

Small modular reactors (SMRs) mark a major advancement in nuclear technology. ‘Small’ refers to their power output; ‘modular’ to their unit-based assembly; and ‘reactor’ to the system where controlled nuclear fission occurs. These compact, factory-built units typically generate 300MWe of power, equivalent to 7.2 million kWh per day.

By comparison, large nuclear reactors produce 1000MWe, or 24 million kWh daily. SMRs are engineered to deliver flexible, scalable, and inherently safe energy solutions.

| Box 1: Emergency planning zone (EPZ) |

| EPZ is the designated area around the nuclear reactor where emergency response measures and procedures have been planned to protect the public and property in case of an accident or emergency. The size of the EPZ depends on the type of reactor, potential hazards, and the applicable regulations. For large nuclear reactors, EPZs typically range from 16 to 80km. For SMRs, EPZs are significantly smaller, sometimes limited to the plant site itself, making them suitable for deployment near industrial sites and urban areas. |

SMRs have a capacity factor exceeding 90%, making them a dependable baseload power source compared to intermittent renewable sources. Modular construction, scalability, rapid on-site assembly, and a reduced emergency planning zone (EPZ) (see Box 1) make them well-suited for deployment in remote areas, industrial hubs, urban centres, and off-grid locations. They have versatile applications, including desalination, district heating, and hydrogen production.

With the market projected to reach $300 billion by 2040, SMRs are set to redefine nuclear energy and play a pivotal role in shaping a sustainable, resilient power landscape. Several companies and startups across various countries are actively developing SMR technologies.

How Small Modular Reactors Work

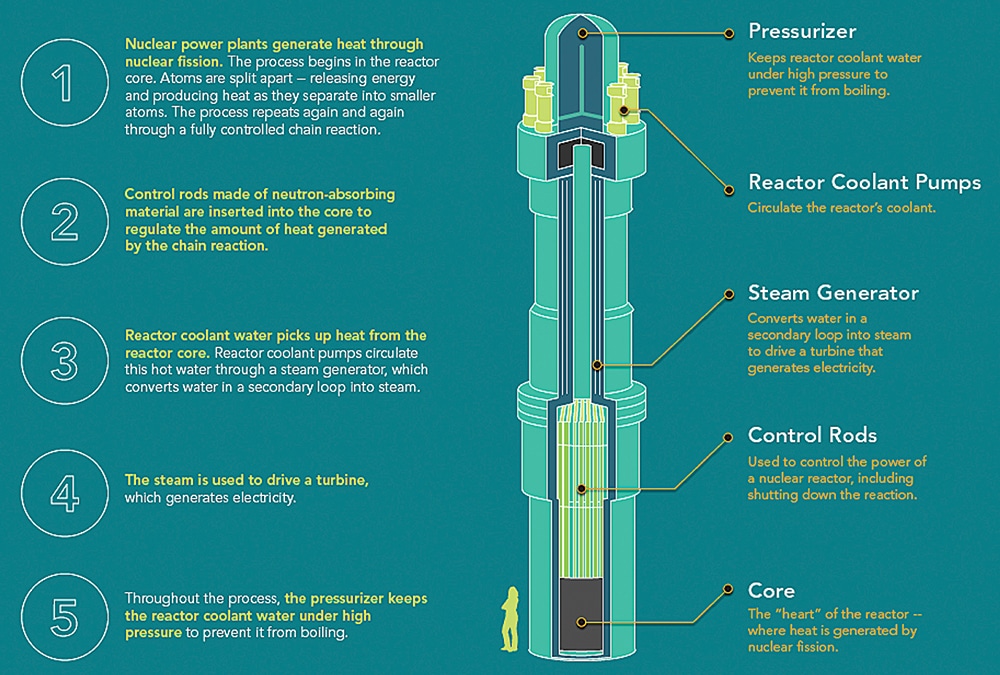

SMRs use the same fundamental nuclear fission process as conventional large-scale reactors to generate heat, which powers a turbine to produce electricity. Key components include a reactor core, coolant system, steam generator, turbine, electric generator, condenser, and passive safety mechanisms.

At the heart of an SMR lies the reactor core, where the controlled fission reaction takes place, releasing a large quantity of heat. This heat is transferred through a coolant system to the steam generator, where it converts water into high-pressure steam that drives a turbine connected to a generator. The used steam enters a condenser, where it is cooled into water and recirculated to continue the energy production cycle.

The reactor core uses control rods made of neutron-absorbing materials, such as boron, to regulate the fission process and prevent overheating. The coolant systems may use light water, gas, liquid metal, or molten salt.

Unlike conventional reactors, which use electrically powered active cooling systems, SMRs rely on natural convection and gravity-driven mechanisms to maintain reactor cooling, even during power failures or emergencies, thereby reducing the risk of overheating.

SMRs Design

SMRs are designed for flexibility, scalability and efficiency. Emphasis is placed on compactness and factory assembly to enable standardised production, enhanced reliability, reduced maintenance needs, and a lower risk of human error.

Their designs typically feature streamlined architecture, integrated systems, fewer components, and advanced digital monitoring technologies. Prefabricated as modular units, SMRs are easily transported via road, rail, or ship, enabling quick deployment in remote locations where building large-scale facilities is impractical.

Refuelling is required every three to seven years, compared to one to two years for conventional reactors. Some advanced designs can operate continuously for up to 30 years without refuelling. Improved fuel recycling and greater efficiency help to minimise radiation levels and reduce radioactive waste.

These designs incorporate advanced manufacturing methods, such as additive manufacturing, 3D printing, powder metallurgy, and hot isostatic pressing (HIP), to enhance material durability and enable reactors to withstand extreme thermal and nuclear conditions. Critical materials are used to improve performance and longevity.

For example, zirconium alloy offers superior corrosion resistance while minimising neutron absorption, and nickel-based superalloys improve heat resistance while reducing radiation exposure.

AI-driven design tools and digital twin technology are employed to simulate reactor performance. Rolls-Royce, for instance, is successfully using these tools for predictive maintenance and operational optimisation.

Designs vary in coolant types, fuel compositions, degrees of modularisation, technology readiness levels, and licensing readiness levels. This diversity presents challenges in selecting a design that suits specific energy demands, regulatory environments, and economic conditions.

Key considerations include radioactive inventory, nuclear safety, transport and handling constraints, and feasibility of fabrication and serial production.

The extent of modularity is influenced by factors such as cost optimisation, site conditions, construction complexity, build time, and overall project risk. A lack of operational data adds further uncertainty to the decision-making process.

Digital Systems: The Electronic Core of SMR Architecture

SMR designs are centred on digital electronic systems that serve as key enablers of scalability, safety, and operational flexibility. These systems act as operational nerve centres, ensuring real-time monitoring, autonomous operation, and consistent performance under normal and emergency conditions by collecting, processing and analysing data from an array of sensors.