The method checks battery images to spot problems before failure. Can this simple step change how we build lithium batteries? Here’s what the study found.

A new algorithm developed at the University of California San Diego could help researchers detect lithium battery failure before it happens using just existing microscope images. This method analyzes how uniformly lithium deposits form on battery electrodes, providing an early warning sign of short circuits and battery degradation.

The tool works with scanning electron microscopy (SEM), a widely used imaging technique in battery labs. Researchers say it can speed up the development of safer and longer-lasting lithium metal batteries, which promise up to twice the energy density of today’s lithium-ion batteries—potentially doubling EV range and extending device battery life.

At the heart of the problem is how lithium forms during charging. If it deposits unevenly, sharp, needle-like dendrites can grow and pierce internal components, leading to short circuits. Until now, scientists judged lithium uniformity visually from SEM images, a subjective approach that varied between labs.

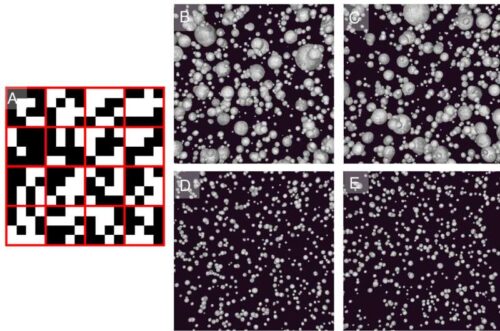

The algorithm brings consistency to this analysis. It converts SEM images into black-and-white pixels, representing lithium and substrate. Then, it divides the image into small sections and counts the white pixels in each, calculating an “index of dispersion” (ID). A low ID signals even lithium spread. A high ID indicates clumping and risk.

The method was first validated on over 2,000 synthetic SEM images with known particle distributions. It then proved successful when applied to real battery electrode images. As batteries were cycled repeatedly, the ID values rose, pointing to increasing unevenness in lithium growth. This was accompanied by a rise in the energy required for lithium deposition, both signs of degradation. Notably, sudden ID spikes were observed just before failure, highlighting the metric’s potential as a predictive tool.

What makes this approach especially impactful is its simplicity and compatibility. Since SEM is already standard in battery research, teams can apply the algorithm directly to images they’ve already collected without needing new hardware or data.

Lithium metal batteries hold huge promise for energy storage and electric mobility, but uneven lithium growth remains a major hurdle. With this new analysis tool, researchers may have a much-needed way to spot problems early, improve designs faster, and bring high-density batteries closer to reality.