A graphene–zinc oxide electrode can prevent corrosion and volume fluctuations in lithium-metal batteries, promising longer-lasting and high-energy storage batteries.

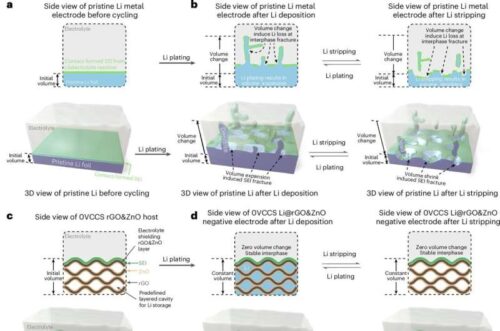

A research team from Shandong University, Zhejiang University, and partner institutes has discovered a nanoengineered electrode material that could significantly advance lithium-metal batteries. The material integrates reduced graphene oxide (rGO), known for its electrical conductivity, with zinc oxide (ZnO), a ceramic recognised for stability and electrochemical activity. The new electrode material solves two issues: electrode expansion and electrolyte corrosion, and marks a potential step towards safer, longer-lasting, and more efficient lithium-metal batteries. The initial experiments support that it does not expand or shrink during charging and discharging.

“We attained a record efficiency of 99.99–99.9999% and a coulombic efficiency of almost 2,000 cycles, surpassing the critical >99.9% threshold for viable Li-metal batteries. We solved the core challenge of volume-change-driven Li degradation, demonstrating for the first time that near-perfect Li reversibility is achievable,” said Chen, co-senior author of the paper published in Nature Nanotechnology.

The objective was to create an electrode that maintains a stable volume while completely shielding lithium from corrosive electrolytes inside the cell. Laboratory evaluations showed that the rGO–ZnO composite fosters the formation of a durable solid–electrolyte interphase (SEI), a crucial protective layer that separates electrodes from electrolytes.

Lithium-metal batteries promise higher energy storage than conventional lithium-ion batteries, enabling longer device life. Yet, they are less stable. The Li-metal electrodes expand and contract during the charging and discharging phases. This varies the volume abruptly, causing cracks and electrical disconnection, affecting battery performance. This ruptures the SEI. Once damaged, the SEI exposes lithium to irreversible corrosion, inhibiting the >99.9% coulombic efficiency (CE) which is needed for practical battery use.

“Looking ahead, we are scaling this host design for commercial pouch cells while refining manufacturing processes. We are also adapting its zero-volume-change sealing concept to other battery chemistries (example, sodium-metal anodes) and exploring integrations with solid-state electrolytes to further enhance safety and energy density—aiming to accelerate real-world deployment through industry partnerships in the next 3–5 years,” said Chen.