This article critically examines the growing use of IoT-based electrical safety devices that claim to prevent fires, electrocution, and electrical faults. It questions their technical validity, certification status, system-level effectiveness, and data safety, especially when such products are promoted as complete safety solutions, sometimes even by government agencies.

Our country continues to face serious challenges related to electrical safety, with electrocution deaths and fire accidents caused by short circuits and other electrical faults common in homes and workplaces. In this situation, some products are being marketed as complete solutions, claiming to prevent fires or protect against electric shocks. What is more concerning is that some of these are being promoted by government agencies, which creates confusion and spreads the wrong message that a single device can make an entire electrical system completely safe.

Now, as users and citizens, we need to understand that electrical safety is not just about shocks. It also means protection against heat, arc flashes, lightning, overcurrent, fault current, electromagnetic interference (EMI) and power interruptions. Each of these requires its own design and protection method.

For example, protecting against electric shock involves three layers. These are basic protection, fault protection and additional protection. These methods are clearly explained in IS 732, which is India’s national standard for electrical installations. This standard does not certify products. Instead, it provides guidance on how to design and verify electrical wiring systems.

So if a product claims to be tested or ‘certified under IS 732’, we need to be cautious. The standard talks about things like insulation, enclosures, automatic power disconnection, bonding and the use of residual current device (RCDs). These are system-level protections, not features of a single gadget.

Safe or just looks safe?

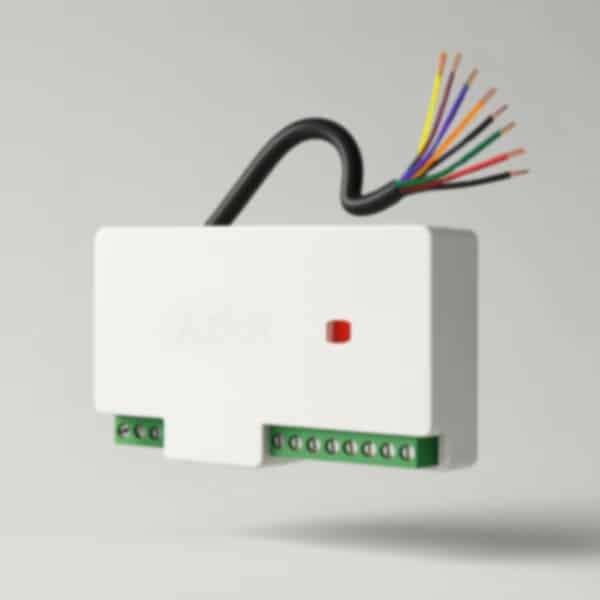

Let us take a closer look at how this electrical safety device actually works and where it might fall short from our perspective as users, engineers, or safety professionals.

We usually install the device right at the source of power, where the main miniature circuit breaker (MCB) or circuit breaker sits. It keeps an eye on key parameters at that central point. Our main circuit is rated for 40A, so we configure the device accordingly. If the current exceeds 40A, it may send an alert or even take action.

But here is the catch. The device does not tell us what is going on in the final branch circuits. If there is an overload further down the line in a 10A or 16A circuit, we might not even know. According to Indian Standard IS 732, we are supposed to protect and log data for each individual circuit. This requires detailed circuit-level information, which the device does not collect.

That leads us to another concern about matching the cable size with the protection device rating. If our MCB is rated for 32A but our cable cannot handle that due to heat or installation conditions, there is a mismatch. IS 732 gives us tables to figure out the right coordination, but it is not clear if the device uses that data or even checks for it.

And what about places like hospitals, where the electrical system is more complex? Hospitals are categorised into Group 0, 1, or 2 based on the criticality of the equipment. Group 2 areas often have both diesel generators (DG) and UPS backups. Should these backups turn on automatically if there is a fault? It is not clear how this device would handle that.

In hospitals, different electrical systems need to work together and follow standard communication rules. But the manual does not say if this device can connect with important equipment like isolation panels, insulation monitoring devices (IMDs), or diesel generators. It also does not tell us if it works with TNS earthing systems or medical power systems, which are commonly used in critical care areas.

The hidden risks

As more of us rely on digital systems for electrical safety and fault detection, we must ask an important question. Is our data safe, and are these systems truly reliable?

The Digital Personal Data Protection Act (DPDPA) introduced in 2023, was a step forward in protecting our personal information. A draft rule under the Act came out in 2025 and may soon be enforced. But here is the problem. Many new electrical safety products, especially those with IoT-based fault detection and SMS alerts, still operate in a grey zone.

We are left with several unanswered questions. Who owns the data these devices collect from our homes or buildings? Where is this data stored, and who gets access to it? If a fault occurs and something goes wrong, such as the data being tampered with or misused, who takes responsibility? When systems are sold to us in the name of safety, they must follow strict rules, not just for our protection, but also to prevent misuse under the guise of smart technology.

Let us also talk about how these systems actually perform. Imagine this. You or I get an electric shock, and only after that does an alert message go out. That is not safety, that is a warning after the damage is done. What we really need is immediate disconnection, limited only to the faulty circuit. But what is happening instead? Many such systems end up tripping entire circuits unnecessarily. We get frustrated and start bypassing them. That defeats the whole purpose.

And then there is the issue of certification. Every product should be certified by a NABL-accredited lab using standard procedures. Standards like IEC 61439 exist for a reason, ensuring that devices like MCBs and distribution boards function as a unit. However, in the case of some of these IoT devices, we do not even know which components were tested or whether the final system has been certified at all. That is a major safety risk.

Even more troubling is how some of these devices get government approval. Sometimes, vague clauses are misused, and because there is not enough technical oversight, flawed products reach the market. We have seen this before in telecom, where fake approvals led to the rollout of non-functional gear in rural areas. Only a whistleblower complaint forced action.

Ultimately, this is not just about blaming field officers. They are often stuck, told to implement what is handed down from the top, even if it puts their jobs or our safety at risk. So the change has to start at the policy level. And it must involve all of us: citizens, engineers, policymakers, and regulators.

Electrical safety cannot be reduced to a single device or a one-size-fits-all solution. It demands a system-level approach grounded in proper design, verified implementation, and strict adherence to established standards such as IS 732 and IEC 61439. As citizens and professionals, we must stay informed and ask the right questions: not just about product features but about certifications, data handling, and real-world performance. The responsibility lies with all of us to advocate for better oversight, demand transparency, and ensure that decisions regarding electrical safety are based on sound engineering principles, not just marketing claims.

| Public safety needs certified solutions, not claims |

| • Some new electrical safety devices, often marketed as IoT-based solutions, are being promoted without approval from key statutory bodies, such as the Central Electricity Authority or the Ministry of Power. • These devices claim to offer full protection against fire or electrocution, but bypass proper testing and safety certification. • Article 21 of the Indian Constitution guarantees the right to life. That includes protection from electrical hazards. Only legally designated authorities can approve such safety technologies. • The Supreme Court has held public officers strictly liable in past cases of fire tragedies. Endorsing uncertified devices could lead to legal accountability. • IoT tools can help with data and monitoring, but placing a ‘black box’ and calling it a full safety system is misleading and risky. • Government departments must ensure any promoted device meets established safety standards and is cleared by relevant authorities |

Table – IoT Electrical Safety and Monitoring Devices: Claims and Limitations

| Product Type | Common Claims | Gaps/Limitations |

| Smart Electrical Auditor, IoT Black Box | Monitors 20+ electrical faults, auto protect | No branch circuit logging; system-level gap |

| IoT-Enabled Fire Prevention Device | Real-time fire/electrocution prevention | Not certified for full panel; lacks fault isolation |

| BMS/EMS-adapted IoT devices | Adds alerts/app to multi-meters | Monitoring only, no protection function |

This article is from a webinar on ‘IoT Device for Electrical Safety – Fact vs Fiction’ from the National Federation of Engineers. It was transcribed and curated by Nidhi Agarwal, Senior Technology Journalist at EFY.