Struggling with lost assets and wasted hours on the shop floor? A light-powered tracker promises real-time visibility without batteries. Find more!

Tracking assets across factories, warehouses, and industrial sites has long been a manual, time-consuming process. Workers spend hours locating equipment or materials, while companies struggle with delays, lost items, and lack of real-time visibility.

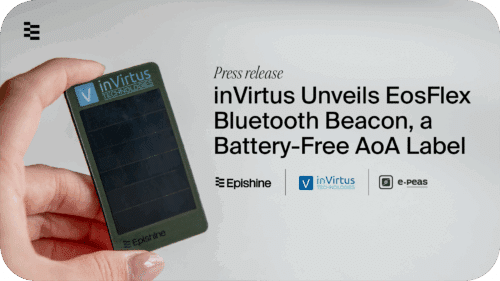

EosFlex, a new beacon from inVirtus Technologies, is designed to address this gap. It enables precise indoor positioning using Bluetooth Low Energy (BLE) with Angle of Arrival (AoA) technology, helping companies automate asset tracking instead of relying on manual checks. This shift promises smoother operations and reduced downtime across large sites.

A major challenge with existing tracking devices is maintenance—especially replacing or recharging batteries. EosFlex removes this barrier by running on indoor light. It integrates solar cells from Swedish company Epishine and ultra-low-power energy management from Belgian company e-peas, allowing it to harvest and store energy without relying on disposable batteries. Even in complete darkness, the device continues working for up to three weeks.

For industries balancing efficiency and sustainability goals, EosFlex offers both. It avoids silicon and rare earth materials, operates entirely on ambient light, and is available in multiple sizes and customizable colors to suit different environments.

By combining energy autonomy with precise location tracking, EosFlex gives industries a tool to streamline operations while cutting maintenance costs and environmental impact.

“An early use case with Thales has shown clear results, saving 30 minutes on part movements, up to 2 hours when locating equipment, and cutting vehicle and shelter setup from hours to seconds, ” said Raphael Pantais, CEO at Invirtus Technologies. We are proud to bring this breakthrough to market together with Epishine and e-peas,”