Tiny gears built on silicon wafers use laser beams to spin instead of mechanical parts.

Researchers at the University of Gothenburg build gears that are smaller than the width of human hair. These micro-gears run on laser light instead of mechanical parts.

This micro-gear is powered by the interaction between the incoming light and the silicon surface . By deflecting the incoming light, the silicon surface induces a force on the rotating gear in the opposite direction due to the phenomenon called the conservation of linear optical momentum.

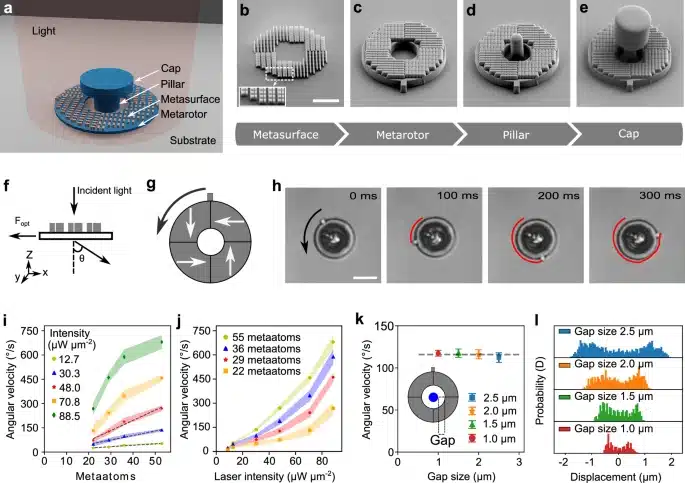

Scientists build these tiny gears onto chips by layering Silicon materials, carving patterns with light, and using four chemical steps to shape and release them. The motors are then fitted with small supports and gold mirrors so they can move and interact with light.

To test them, researchers shine a laser through a microscope to make the gear spin and change direction. Records the movement with a camera, while also checking that the motors do not stick and can keep running smoothly. The team uses a special liquid to keep the gears run smoothly on the surface.

The gear spins because its patterned surface bends laser light, and the push from the light makes it turn. The faster it spins depends on the light intensity: at low intensity, speed rises steadily, but at higher intensity, the gears spin even faster, but in a nonlinear way.

The motor, not energy efficient but works for hours without damage. It slows down if the liquid gets dirty, though cleaning restores it. Smaller gaps make the rotor more stable, and researchers even make rotors as small as 8 micrometres, showing many can spin together under one laser beam.

Because the gears are built on the chips with no mechanical contact, they can be scaled to form more complex systems. The smallest gears measure 16 to 20 micrometres, similar in size to human cells.