The 3D laser profile sensor provides micrometre-level 3D measurement accuracy for inline inspection in electronics and manufacturing.

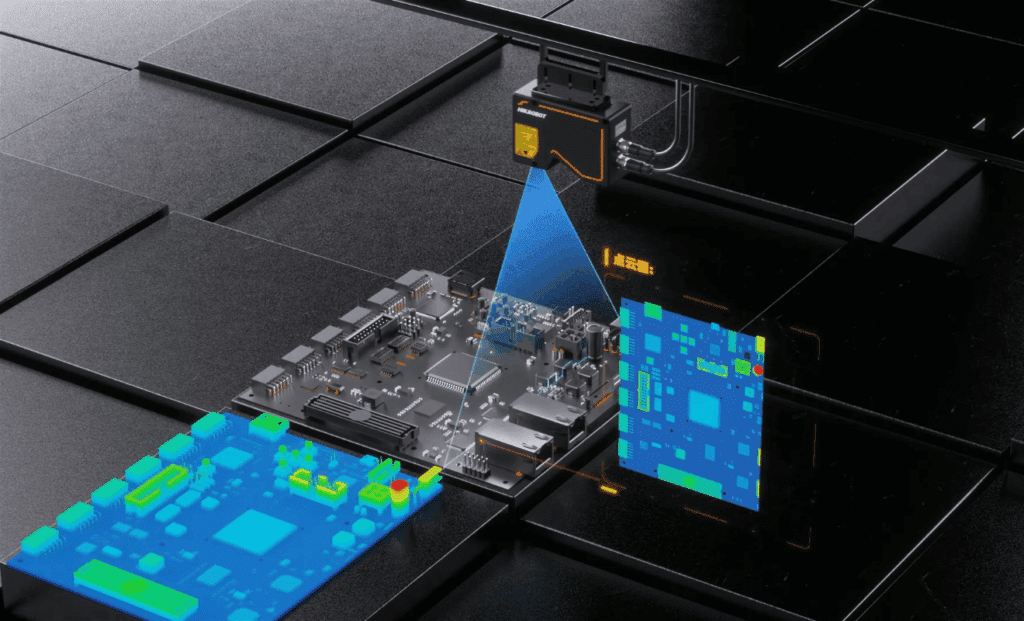

Hikrobot introduces a 3D laser profile sensor, to capture 3D data of the object without any physical contact with the object like PCBs, batteries. The sensor is designed for high-precision measurement and is aimed at industries such as consumer electronics, lithium batteries and printed circuit boards. Its role is to provide reliable data for inspection and quality control where direct contact is not possible or practical.

The device works on the principle of laser triangulation. A 405 nm blue laser projects a line onto the object being measured. The reflection is captured by an image sensor, and built-in algorithms calculate the object’s three-dimensional contour. As the sensor or the object moves, these contours are combined to create a complete 3D profile.

The optical design includes a large-iris lens, high dynamic range sensor and Scheimpflug arrangement to keep images clear across the field of view. This helps maintain accuracy when working with different materials and surface conditions.

The sensor has an integrated processing unit. This allows it to handle image processing internally at speeds up to 19 kHz. A hardware-accelerated acquisition module can record data at up to 49 kHz. These figures mean the device can capture and process data in real time without overloading an external computer.

Key Features

- Gives 3D images and depth data in real time

- Can process data at speeds up to 19,000 times per second

- Captures images at frame rates up to 49,000 per second

- Measures with very fine accuracy down to 0.05 pixels

- Works with different surface brightness using HDR and multi-exposure modes

Accuracy is enhanced with features such as subpixel resolution down to 0.05 pixels, multi-exposure fusion to capture both bright and dark areas, single-frame HDR for surfaces with mixed reflectivity, and suppression of stray light that might otherwise distort results.

Post-processing filters are included within the device, such as spatial and time-domain filters, so the host system does not need to run them.

The sensor is presented for use in production environments where fast, precise and repeatable measurements are required, including inspection of electronics components, battery cells and circuit boards.