By combining magnetic sensing and digital processing, the encoder converts the machine’s rotation into precise position data.

As robots and motor-driven systems become more complex, precise and reliable position sensing has become essential. Modern automation and robotics require encoders that can deliver accurate feedback, tolerate installation variations, and withstand dust, vibration, and magnetic interference.

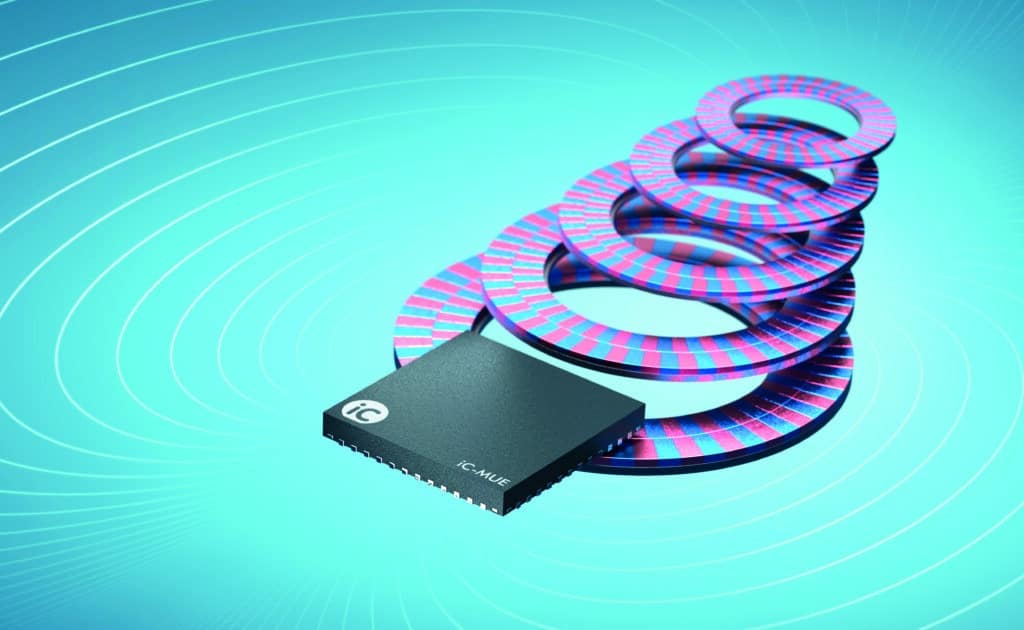

To meet these needs, iC-Haus introduces the iC-MUE (Magnetic Hollowshaft Encoder), a Magnetic system-on-chip encoder designed specifically for hollow shaft applications.

The chip is a system-on-chip (SoC) device, which means all the key sensing and processing functions are built into one small IC. It detects the position of a rotating magnetic field and converts it into digital or analogue signals that control a machine’s movement. This makes it useful for robotic arms, motor drives, and automation systems that require accurate feedback.

The design is based on the company’s earlier iC-MU series but adds better flexibility and performance. Using a decimal Nonius principle, the chip can adapt to different magnetic scale sizes, from 20 mm to 85 mm in diameter. It can measure rotation angles with a resolution of 21 bits and accuracy of about 0.04 degrees for a 44 mm magnetic scale.

To make installation easier, the chip includes built-in calibration. Users can adjust settings through software or at the press of a button. It also corrects alignment errors automatically and filters out magnetic noise using differential magnetic scanning, which improves reliability in industrial environments.

The chip supports multiple communication interfaces such as BiSS, SSI, SPI, ABZ, UVW, and analogue outputs, so it can connect to different control systems. It also has an I²C interface for configuration and diagnostics, and can be linked to an external multiturn sensor for extended position tracking.

Operating on 3.3 to 5 volts and across -40°C to 125°C, it includes a temperature sensor, safety-ready analogue output, and built-in diagnostics. These features make the chip suitable for factory automation, motor feedback systems, and robotic applications where compact, precise, and reliable motion sensing is essential.