Researchers from the University of Turku replaced the complex RGB chemistry and rare materials in white OLEDs with a single blue emitter inside a microcavity, which results in tunable white light, lower costs, and a cleaner path toward sustainable OLED lighting.

Researchers at the University of Turku have unveiled a streamlined approach to white OLED lighting that could significantly reduce both cost and environmental impact. Their new design eliminates the usual RGB-dopant chemistry and the costly transparent electrode material indium tin oxide (ITO), by using a single blue emitter inside a microcavity structure to produce tunable white light.

Traditional white OLEDs often depend on three separate colour-emitting dopants (red, green, blue) mixed into a host organic layer, plus an ITO transparent conductor. That complexity drives manufacturing cost, material waste and reliance on rare materials. In contrast, the new device uses a single sky-blue TADF (thermally activated delayed fluorescence) emitter called DMAC-DPS, sandwiched between two standard aluminium mirrors that serve simultaneously as electrodes.

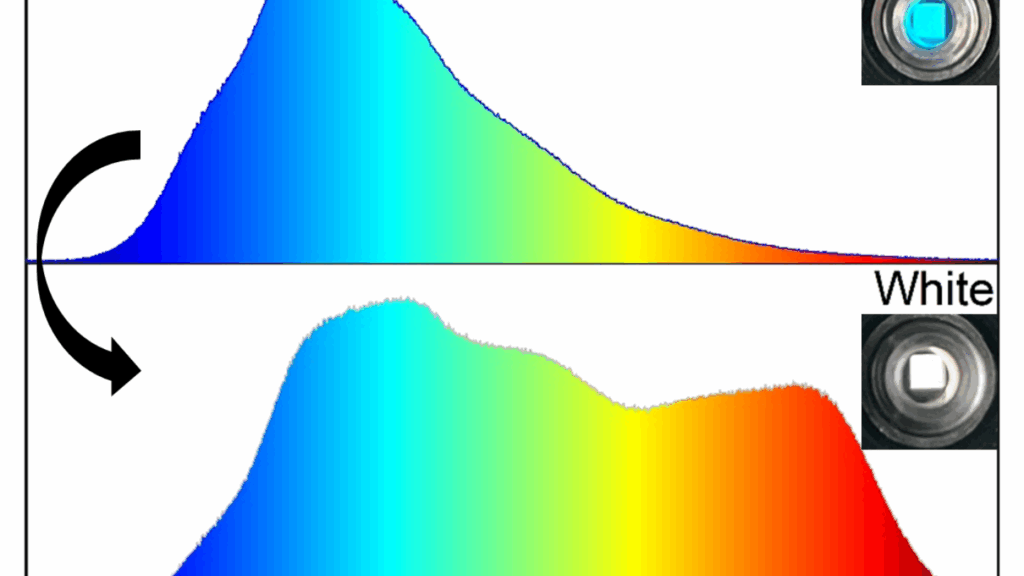

By adjusting the thickness of the emitter layer (cavity length) and via the interaction of surface plasmon polaritons with the microcavity mode, the team achieved white emission tunable between roughly 3 790 K (warm white) and 5 050 K (cool white) — all without extra host-guest chemistry or RGB mixing. This “top-emitting” architecture does more than simplify the stack: because the electrodes are standard aluminium and no ITO is required, it plugs into existing vacuum deposition lines more easily and opens up possibilities for flexible, reflective or unconventional form factors such as smart-building panels and ultra-thin luminaires.

The researchers say the key achievement is “getting more with less” — leveraging optical design to replace chemical complexity and removing heavy-metal dopants and ITO to make OLED lighting more sustainable. Looking ahead, the team plans to focus on boosting brightness, efficiency and long-term stability so the concept can mature from lab demonstrator to real-world lighting products. If successful, this could mark a meaningful shift for OLED lighting: simpler manufacturing, fewer scarce materials, and cleaner supply chains — all while delivering high-quality white light.