Most robot motors use old IGBTs. They get hot and take up space. A new GaN design consumes less energy, is more compact, and exhibits improved performance.

Most servo drives in industrial and collaborative robots face efficiency and size limitations due to the use of IGBT-based inverters. These drives, which usually operate from a single-phase 200–230 VAC input and produce a 320 VDC bus with input power below 3 kW, often use IGBTs switching at 8–16 kHz. The problem is that IGBTs have high power losses, which require bulky heat sinks that can make up over 30% of the inverter’s size. This reduces power density and adds weight—both critical concerns for motor-integrated servo drives in robotic arms and factory automation, where compact, lightweight systems directly affect motion performance.

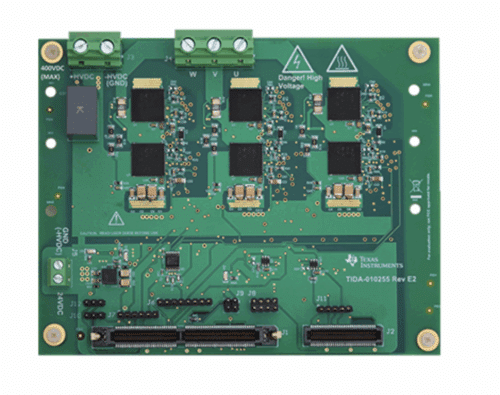

TIDA010255, a reference design from Texas Instruments (TI), addresses these issues by implementing a high-efficiency 3-phase power stage utilizing six fast-switching GaN FETs. These devices integrate drivers, protection, and temperature reporting, and are controlled by a hot side MCU. By using GaN instead of IGBTs, the design achieves significantly higher switching efficiency, even within the same PWM frequency range, reaching a peak efficiency of 99.4% at 16 kHz PWM. The result is over four times lower power loss compared to traditional IGBT inverters at 7 ARMS output current. This improvement supports smaller form factors, higher power density, and reduced thermal requirements, helping meet IEC 61800-9 energy class IES2 standards.

The inverter design includes integrated drivers, protection, and temperature monitoring features to simplify circuit design and improve reliability. Integrated buck converter modules with inductors and bootstrap power supplies reduce external component count and overall footprint.

Precise current measurement is achieved using shunt resistors and isolated delta-sigma modulators for phase-current sensing, ensuring accurate and linear results. Because the MCU ground is tied to the power ground, DC-link and phase voltage sensing do not require isolation. A small, non-isolated delta-sigma modulator measures the DC-link voltage, while analog phase-voltage feedback enables the evaluation of sensorless control techniques, such as InstaSPIN-FOC.

For evaluation, the design features a 3.3 V I/O interface with a 180-pin MCU connector and a standard header for interfacing with other controllers. It was tested at 320 VDC and 16 kHz PWM without a heat sink, providing a continuous 3-phase output of up to 7.7 ARMS at room temperature. For higher current or temperature testing, a heat sink can be attached to the PCB through the provided mounting holes.

This makes the reference design suitable for engineers developing single and multi-axis servo drives for industrial and collaborative robots. It demonstrates how GaN-based inverters can reduce energy consumption, decrease inverter size, and increase power density, key improvements for compact motor-integrated servo drives used in 6-axis robotic systems and other factory automation applications.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.