2D polymer film that’s nearly impermeable to any gas may soon protect chips, sensors, OLEDs, and next-gen solar cells from corrosion potentially extending device lifetimes by years with a coating thinner than light itself.

Researchers at Massachusetts Institute of Technology (MIT) have developed an ultra-thin polymer film that shows unprecedented resistance to corrosion by being essentially impermeable to gases. The material, a two-dimensional polyaramid named 2DPA-1, could pave the way for protective coatings across solar panels, infrastructure, food packaging and more.

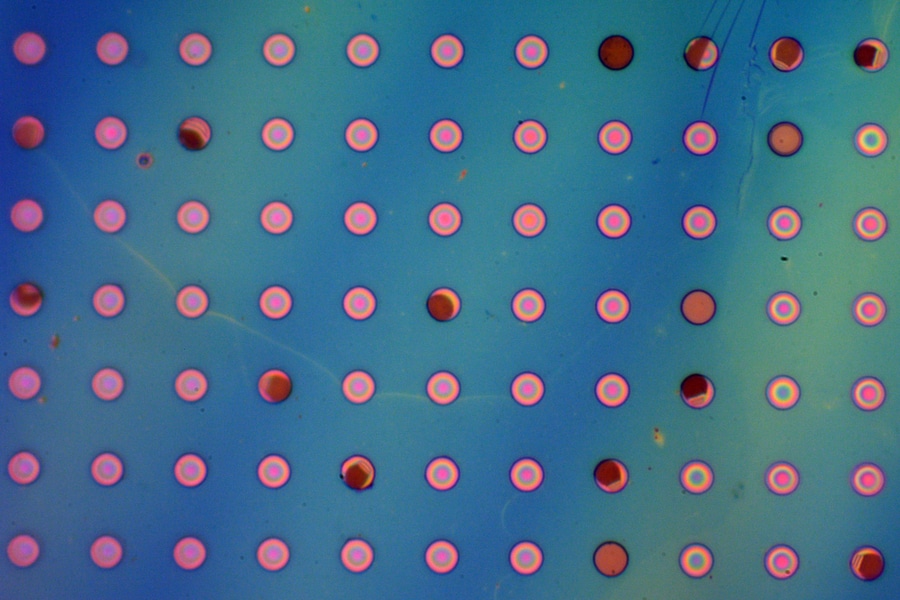

Dubbed “molecularly impermeable”, 2DPA-1’s performance eclipses conventional polymer films. In experiments, bubbles formed from the material did not collapse; some inflated in 2021 remain intact today. When tested against nitrogen, helium, argon, oxygen, methane and sulfur hexafluoride, its gas-permeability was at least 1/10,000 of any known polymer and approached the near-absolute barrier performance of crystalline materials like graphene.

What makes it so special is its structural design: the polymer self-assembles into flat molecular disks via hydrogen bonds, stacking into layers that leave virtually no voids for gas molecules to slip through. Unlike traditional polymers whose tangled chains form microscopic gaps this material packs tightly and uniformly, delivering its barrier effect.

Beyond just boasting materials-science credentials, it is scalable. The team demonstrated that a film only 60 nanometres thick could extend the life of a perovskite solar-cell crystal by weeks, signalling real-world potential for a wide range of applications. The researchers say the coating could protect everything from bridges, vehicles and aircraft to packaged food and medications.

According to MIT’s Carbon P. Dubbs Professor of Chemical Engineering, Michael Strano, the material “behaves like graphene … but you would never confuse it with a perfect crystal.” Indeed, the ease of applying this polymer as a solution-phase film over large surfaces may give it a manufacturing edge over graphene, which struggles to scale in real-world coatings.

While the research remains at laboratory scale, its implications are wide-ranging: imagine solar farms that resist the elements far longer, infrastructure less prone to rust and failure, and food or medicine packaging with dramatically extended shelf life. A film thinner than the wavelength of visible light, yet stronger than steel per its earlier iteration, could become one of the most promising protective materials of our era.