High-voltage DC systems can be risky if power isn’t switched safely or status isn’t clear. See how a small, reliable device can make them safer and easier to manage.

High-voltage DC systems in electric vehicles (EVs), industrial energy storage, and uninterruptible power supply (UPS) setups face a common challenge. They need to safely disconnect power while ensuring precise, reliable feedback on the contactor’s state. Failure to do so can risk equipment damage, downtime, or safety incidents. Engineers need compact, robust solutions that deliver both high performance and clear status monitoring.

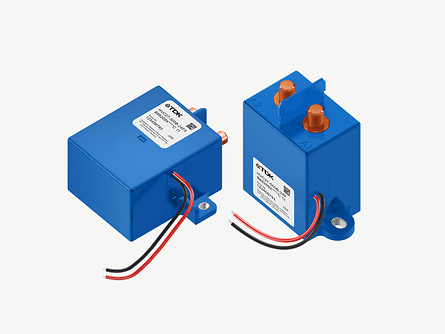

TDK’s HVC27*MC series addresses this need. These compact, gas-filled DC contactors provide accurate contact position feedback through a mechanically linked, normally-closed auxiliary mirror contact compliant with IEC 60947-4-1, making them ideal for safety-critical applications in battery disconnect units, energy storage systems, DC fast charging, and uninterruptible power supplies.

Measuring 86.5 × 95 × 44 mm and weighing 530 g, the series handles DC voltages up to 1000 V with continuous currents of 300 A, 400 A, and 500 A, and single-shot capability of 900 A at 1000 V in under 20 ms. Bidirectional, polarity-free main terminals and a hermetically sealed ceramic arc chamber ensure safe disconnection under demanding conditions.

Available with 12 V or 24 V coil voltage and certified to UL, CE, and UKCA standards, these contactors are ready for global deployment. The robust design meets stringent vibration and shock requirements, supporting high-voltage mobility systems, industrial machinery, and commercial vehicles. By combining compact size, reliable switching, and advanced contact feedback, the series helps engineers meet regulatory and functional safety standards while simplifying system design.

Key features include a single coil with connector eliminating coil termination, bidirectional main terminals, the normally closed auxiliary mirror contact, and RoHS compliance for environmentally responsible deployment.