E-waste has valuable metals, but recycling is dirty and harmful. A new natural method can safely recover metals and make them ready for use.

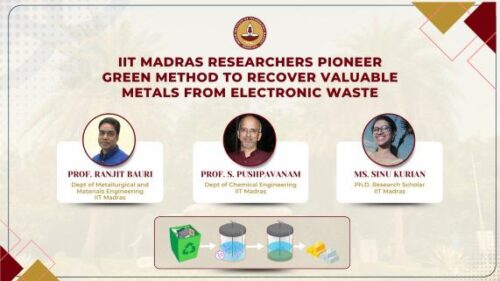

IIT Madras Researchers pioneer Green Method to recover valuable metals from Electronic Waste

Electronic waste is one of the fastest-growing waste streams in the world. It contains valuable metals such as copper, gold, and iron, but conventional recycling methods rely on strong acids and other harsh chemicals. These processes create toxic waste, use a lot of water, and often produce impure metals that need more processing. This makes recycling unsafe, costly, and harmful to the environment.

Researchers at IIT Madras have developed a method to recover metals from e-waste in a way that is safer and more environmentally friendly. The method uses solvents made from natural compounds that dissolve metals without producing toxic waste.

The process starts with a solvent made from thymol (from thyme) and capric acid, which can dissolve copper. The copper is then extracted using trisodium citrate, a non-toxic chemical, and converted into copper nanoparticles. By adjusting the pH, the process can produce different forms of copper, including copper oxide nanoparticles and pure copper metal. The method also works for iron and has been tested on real e-waste samples like printed circuit boards and copper sheets.

This approach solves several problems at once: it reduces environmental pollution from e-waste, cuts down on water and chemical use, produces metals in usable forms, and lowers the need for mining new metals. It benefits recycling companies, industries that use metals or nanomaterials, and society by creating safer and cleaner recycling systems.

Laboratory tests have validated the process for multiple metals and real e-waste samples. The next steps include scaling it up for industrial use, improving solvent recyclability, and finding cost-effective alternatives. IIT Madras is also exploring collaborations with industry and recycling companies for pilot-scale testing and real-world deployment.

The research demonstrates a practical way to recover metals while reducing environmental harm and supporting India’s circular economy and sustainability goals.