With milligram level automated correction and AI based diagnostics, the machine provides stable performance, supporting self reliant production in automotive, aerospace, and energy sectors.

High precision balancing is critical in manufacturing, where tiny mass imbalances in rotating components impact performance, reliability, and safety. Industries such as automotive, energy, aerospace, and defense require equipment meeting strict standards, yet most high end systems are imported and rely on manual or semi automated operation, limiting repeatable accuracy.

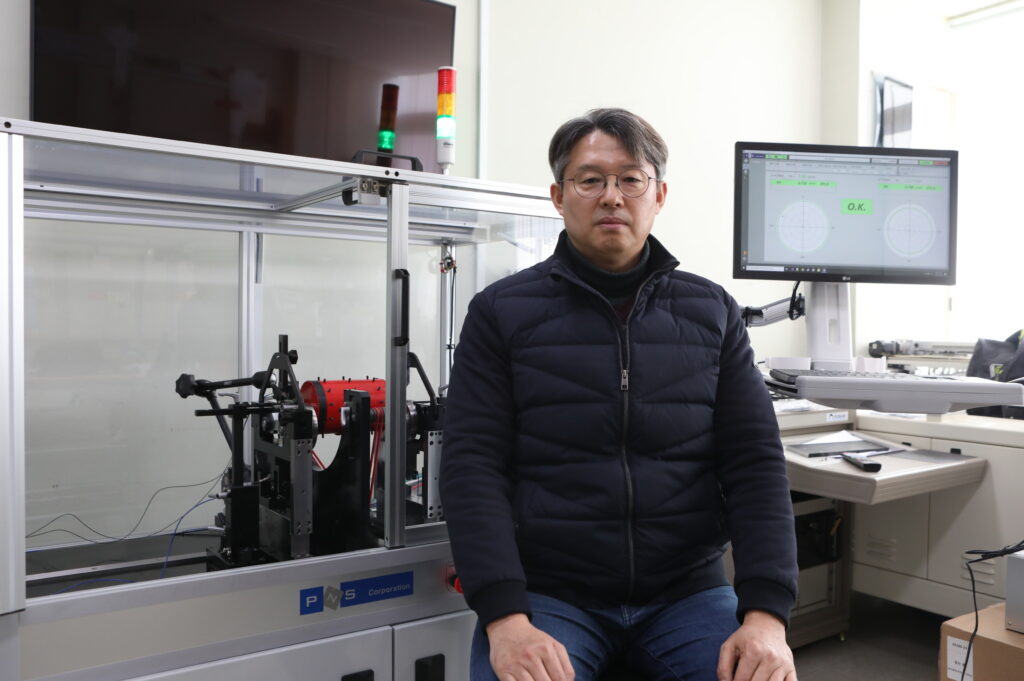

South Korea has addressed this gap through the domestic development of a high precision automated balancing machine by the Korea Institute of Machinery and Materials, in collaboration with PNS Co Ltd. Led by Dr Byeongock Kim and supported by the Ministry of Trade Industry and Resources, the project resulted in a system capable of automatically measuring and correcting milligram level mass imbalances in real industrial environments.

Beyond core measurement and correction, the system introduces an intelligent architecture designed for industrial reliability. High sensitivity vibration sensors combined with high speed signal processing enable precise imbalance detection, while AI based algorithms automatically filter noise and abnormal signals to maintain repeatable accuracy. A closed loop correction algorithm optimizes cutting speed, depth, and position based on component geometry, material properties, and rotational speed, enabling high precision correction with built in self calibration.

Operational stability is further strengthened through intelligent diagnostic logic that continuously monitors sensor conditions, measurement errors, and system behaviour in real time. A modular design allows rapid adaptation to user requirements and direct integration as a standard quality control system on production lines.

Key features of the machine include:

- Milligram level imbalance detection using vibration based measurement

- AI driven signal processing for noise reduction and accuracy

- Closed loop correction with self calibration

- Real time system diagnostics

- Modular design for production line integration

Dr Byeongock Kim, principal researcher at KIMM, says, “This development is significant in that it establishes domestic technological self-reliance in automated balancing machines, which are classified as strategic materials, and demonstrates their successful application in real industrial environments.”

With the research, the researchers also plan to continue to advance the technology and expand its application so that it can serve as a core equipment for enhancing quality and reliability in precision manufacturing processes.