Boards are getting smaller, but power needs keep rising. An inductor design shows how engineers can save space without losing performance or reliability.

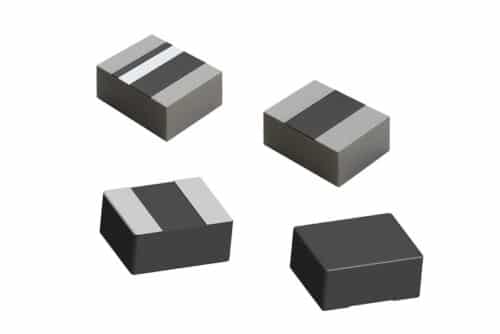

Design engineers working on compact power circuits often struggle to fit high-current inductors into shrinking PCB layouts without sacrificing efficiency, thermal margin, or reliability. This becomes even harder in automotive and industrial systems, where space is limited, temperatures are high, and mechanical stress is constant. Vishay Intertechnology addresses these constraints with new 0806 and 1210 size power inductors that deliver comparable electrical performance in much smaller footprints, helping designers free up board space while maintaining stable operation.

By reducing board area by up to 64% in the 0806 size and 11% in the 1210 size, the inductors allow denser layouts and simpler routing in DC/DC converters, filtering stages, and noise suppression circuits. Lower DC resistance improves power efficiency, which is critical in battery-powered systems, dense computing platforms, and high-current automotive electronics. Wider inductance options also make it easier to tune designs without switching to larger packages.

In automotive applications, reliability under heat, vibration, and shock is a key concern. Vishay’s automotive-grade versions operate up to +165 °C and use side and bottom terminal plating to form strong solder joints, improving mounting strength and inspection. This makes them suitable for power stages in infotainment systems, ADAS, LiDAR, sensors, braking systems, and engine control units, where mechanical durability and thermal stability directly affect system reliability.

For commercial and industrial electronics, compact size and layout flexibility are often the main challenges. Vishay’s bottom-only terminal plating reduces the land pattern size, enabling tighter PCB designs in CPUs, SSD modules, networking equipment, automation systems, medical devices, and precision instruments. Lower resistance helps reduce power loss and heat generation in high-density designs.

Across both variants, the powdered iron core and fully encapsulated construction reduce magnetic interference, limit noise, and maintain stable inductance across load and temperature changes. This helps prevent crosstalk, improves signal integrity, and supports higher transient currents without saturation, which is important in fast-switching power converters and sensitive electronic systems.