The requirements of the defence and aerospace sector have pushed the test and measurement (T&M) industry to the edge, as system reliability and integrity are of utmost importance in this mission-critical sector. This article discusses the latest trends in T&M for defence and aerospace

Dilin Anand

NOVEMBER 2012: In critical areas such as defence and aerospace, test and measurement acquires a whole new level of importance. The cost of testing may be high, but a failure could be catastrophic. This puts the stress on test engineers to acquire accurate data, thus creating the need for special equipment that ensure total data integrity and reliability. To keep up with the demands from this space, the instruments have been consistently upgraded over the years, by making use of the advancements made in electronics.

NOVEMBER 2012: In critical areas such as defence and aerospace, test and measurement acquires a whole new level of importance. The cost of testing may be high, but a failure could be catastrophic. This puts the stress on test engineers to acquire accurate data, thus creating the need for special equipment that ensure total data integrity and reliability. To keep up with the demands from this space, the instruments have been consistently upgraded over the years, by making use of the advancements made in electronics.

Increased sophistication, and demanding requirements

The Indian armed forces are currently investing in a wide number of advanced technology programmes, and this is driving the entire supply chain to invest in more advanced equipment including test and measurement equipment. It also means that focus is shifting from a large volume of a small number of items to smaller volumes of a greater variety of equipment.

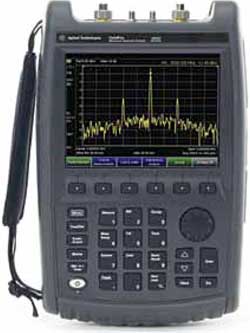

Test and measurement companies have sensed this trend, and have already begun making changes to their strategies. Stephen Hire, GM of Aeroflex Asia, explains, “Test and measurement companies need to design and deliver flexible solutions that can be easily utilised for multiple projects so that capital investment is protected. Additionally, these trends require sophisticated but easy-to-use test equipment that meet diverse needs of production and field testing.”

[stextbox id=”info”]

There is a high concentration of defence equipment manufacturing companies in Bengaluru. Maintaining the highest level of quality is a top priority for these businesses

— Bruce Bolliger, vice president for Tektronix Service in Asia

[/stextbox]

[stextbox id=”info”]

New types of tools are needed to enable analysis of live signal environments and rapidly detect and identify suspicious or illegal radio activity

— Stephen Hire, GM of Aeroflex Asia

[/stextbox]

Jon Friedman, aerospace & defence and automotive industry market-ing manager, MathWorks, expects model-based design to continue as a standard for companies throughout the aerospace industry, over the next few years too.

“In 2012, the DO-178 standard was revised to the C level, which contains four technology-based supplements. One of these is focused on model-based development and verification. Going forward, as engineers focus on this supplement, they will need to identify model-based activities that can be considered for credit, such as when models and simulations can be used to assess the correctness of high-level and low-level requirements,” Friedman says.

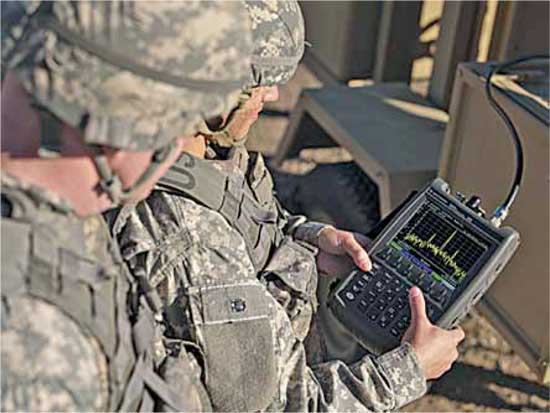

As technology evolves, so does the nature of aerospace and defence missions. Remotely piloted vehicles—land, sea and air—scout ahead and stream data and images back. Secure wireless transmissions deliver voice, data and images to war-fighters, providing them real-time intelligence to identify between friend and foe.

Gautam Awasthi, GM-marketing, EMG, Agilent Technologies India, adds, “Advanced avionics and guidance systems ensure precise journeys for military and commercial aircrafts. High-performance test equipment must be readily available to test the systems of today and tomorrow—across the life of those systems. The cost of ongoing, long-term support must also be affordable, and in line with the shifts between programme and operational budgets.”

Companies like Tektronix have already brought out multi-vendor calibration programmes to help firms reduce their test equipment management costs. With programmes like these, firms require just one supplier to manage their calibration programme, reducing management costs and increasing the quality of the calibration itself.

Calibration, with metrology at its heart, is a requirement for contractual relationships among many businesses, and even more rigorously a part of businesses’ transactions with government entities and the military.

Bruce Bolliger, vice president for Tektronix Service in Asia, says, “There is a high concentration of defence equipment manufacturing companies in Bengaluru. Maintaining the highest level of quality is a top priority for these businesses.”

Accredited calibration is a very comprehensive level of calibration service. Typically, this option is selected when the instrument owner must comply with a contract requiring accredited calibrations. The company that owns the instrument may be involved, for example, in the manufacture of products related to safety, health or military applications. The end-users of these products rely on zero-defect manufacturing and test policies. This is where the accredited calibration comes in; it is based on rigorous procedures executed by competent personnel and documented in great detail.

Standards bring order to chaos

Proper calibration means compliance with standards, including traceability requirements, documentation, processes and competencies. A compliant calibration means confidence in the results. Without compliance, the calibration—and its measurement results—may be invalid. An instrument calibrated with non-compliant tools or procedures is itself non-compliant, although that fact may not be known until the unit starts to cause problems—explains Tektronix’ white paper on ‘Metrology and Calibration.’