It suppresses dendrite growth and boosts energy density to nearly double that of today’s lithium-ion cells—promising safer, longer-lasting electric vehicles with extended driving ranges.

A team of researchers from POSTECH and Chung-Ang University has unveiled a breakthrough in lithium-metal battery (LMB) design that could pave the way for safer, higher-capacity batteries in electric vehicles (EVs). Published in Advanced Materials, the study introduces a 3D porous electrode structure that promises to extend EV driving range while addressing one of the most stubborn safety issues in next-generation batteries — dendrite formation.

While EVs have proven to be far safer than internal-combustion vehicles, battery fires remain a major concern. Out of roughly 40 million EVs operating globally, about 500 verified battery-related fires have been recorded since 2010 — a risk of just 1 in 100,000 vehicles, according to the International Council on Clean Transportation. However, when fires occur, they are difficult to control, underscoring the need for safer, more stable energy storage systems.

Lithium-metal batteries are seen as the next step beyond lithium-ion technology, offering nearly double the energy density — potentially boosting EV range by up to 70%. Yet, their commercialization has been hampered by dendritic lithium growth during charge cycles, which can pierce separators, trigger short circuits, and lead to catastrophic failures.

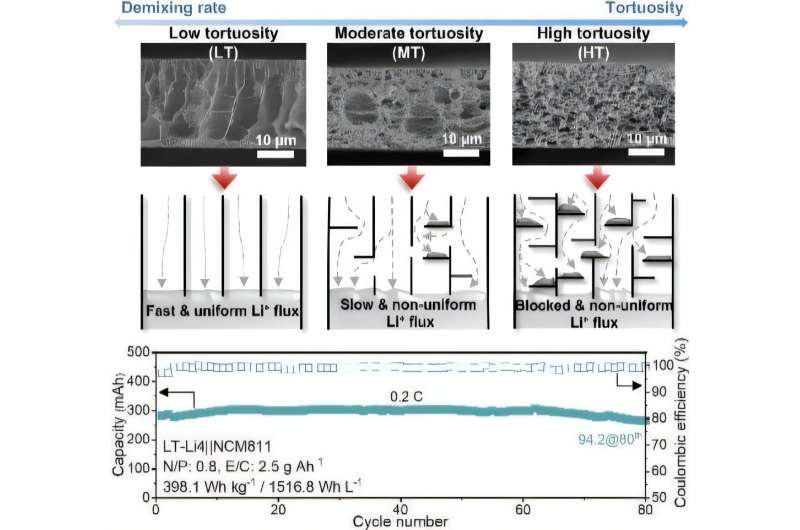

The team developed a low-tortuosity porous host with vertically aligned channels and a built-in gradient of lithium affinity. This structure encourages lithium to deposit uniformly from the bottom upward — much like cars neatly filling the lower floors of a well-designed parking garage.Fabricated using a nonsolvent-induced phase separation (NIPS) process, the electrode combines a polymer matrix with carbon nanotubes and silver nanoparticles for enhanced conductivity. An added silver-coated copper base promotes controlled lithium nucleation, effectively suppressing dendrite formation and improving mechanical stability.

The resulting LMBs delivered impressive energy densities of 398.1 Wh/kg and 1,516.8 Wh/L, far outperforming current lithium-ion batteries (~250 Wh/kg, ~650 Wh/L). Even under realistic EV operating conditions with limited electrolytes and thin anodes, the batteries maintained stability with no short circuits or capacity fade.

According to lead researcher Professor Soojin Park, this dual control over ion transport and lithium growth offers “a turning point toward the commercialization of safe, high-energy lithium-metal batteries.” Co-researcher Professor Janghyuk Moon added that the method’s simplicity and scalability make it promising for mass production.