Empa researchers move closer to creating soft, elastic actuators that mimic human muscles.

Empa researchers have made a significant leap in artificial muscle development by utilizing 3D printing to create soft, elastic, yet powerful actuators. These artificial muscles could one day be used in robotics, medical applications, or even assistive devices, bringing us closer to a future where movement can be controlled at the touch of a button. Their findings were recently published in Advanced Materials Technologies.

Artificial muscles are not just for robots—they have the potential to enhance human mobility, support workers, or even replace damaged muscle tissue. However, replicating the unique combination of power, elasticity, and softness found in biological muscles remains a major challenge.

At their core, artificial muscles function as actuators—components that convert electrical impulses into movement. Traditional actuators, found in everything from car engines to industrial machinery, tend to be rigid and mechanical, making them vastly different from natural muscles. Empa’s Laboratory for Functional Polymers aims to bridge this gap by developing actuators from soft materials using an innovative 3D printing process.

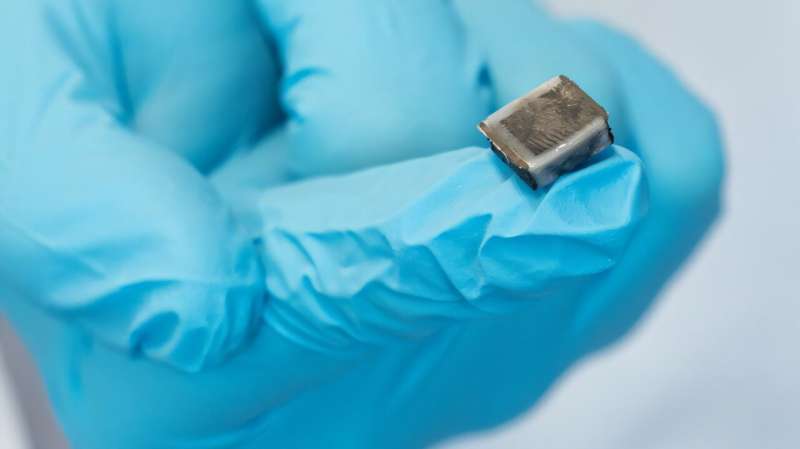

Their dielectric elastic actuators (DEAs) are composed of two silicone-based materials—one conductive and one non-conductive—layered together like interlocked fingers. When an electric voltage is applied, the actuator contracts like a real muscle, then relaxes once the voltage is removed.

Printing these structures is complex since the two materials must remain distinct yet compatible. The challenge lies in ensuring they remain soft enough to respond to electrical stimuli while also maintaining structural integrity.

Empa, in collaboration with ETH Zurich, has successfully developed specialized inks and a custom 3D-printing nozzle to overcome these challenges. This breakthrough is part of the Manufhaptics project, which aims to create a VR glove that provides tactile feedback through artificial muscles.

Beyond VR, these soft actuators have broader potential in robotics, machinery, and even medicine. Researchers believe that with further development, they may one day print artificial muscle fibers thin enough to function like real ones—or even create an entire artificial heart. While that future is still distant, Empa’s work is bringing it one step closer to reality.