A SeoulTech team has developed a 3D-printed auxetic structure that boosts sensor sensitivity, stability, and customization—opening new possibilities for smart insoles, robotic grippers, and next-gen health monitoring.

Researchers at Seoul National University of Science and Technology have unveiled a 3D-printed metamaterial that dramatically boosts the performance of tactile sensors used in wearables, robotics, and healthcare monitoring. The innovation promises more sensitive, stable, and customizable devices for applications ranging from smart insoles to robotic grippers.

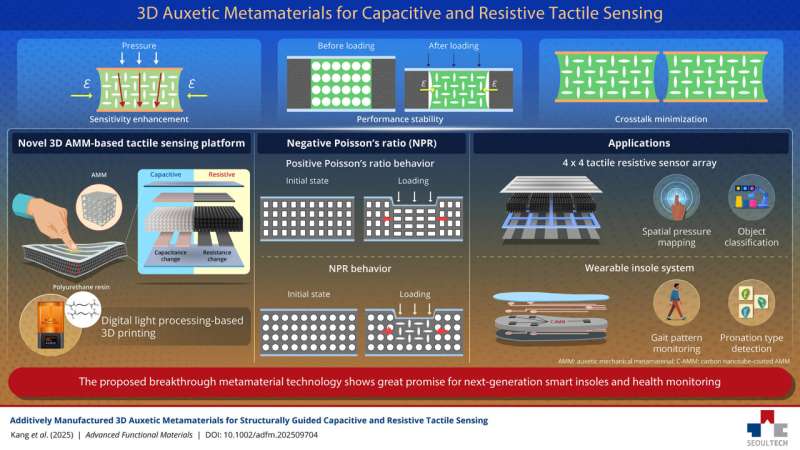

Tactile sensors are already vital in prosthetics, health monitoring, and human–machine interfaces, converting pressure and force into electrical signals. Yet, enhancing both sensitivity and durability has long been a challenge. Enter auxetic mechanical metamaterials (AMMs)—structures with a negative Poisson’s ratio that contract inward under pressure, concentrating strain in the sensing region.

Led by graduate researcher Mingyu Kang with Dr. Soonjae Pyo, the SeoulTech team designed a cubic lattice with spherical voids fabricated using digital light processing (DLP) 3D printing. Unlike conventional porous structures, their auxetic design minimizes lateral expansion, reducing interference when integrated into compact devices such as insoles or robotic hands.

The researchers tested the platform in two sensing modes:

- Capacitive, where pressure alters electrode spacing and dielectric distribution.

- Piezoresistive, where a carbon nanotube coating changes resistance under load.

Both modes benefited from the AMM’s unusual mechanics. “Our design enhances sensitivity through localized strain concentration, maintains stability even when confined in rigid housings, and minimizes crosstalk between adjacent sensors,” Kang explained. Two proof-of-concept demos highlighted its versatility: a tactile array capable of spatial pressure mapping and object classification, and a wearable insole system that monitored gait patterns and detected pronation types.

The auxetic sensor platform can be integrated into health monitoring systems, robotic hands, and rehabilitation devices without compromising comfort or sensitivity. Its scalability and material independence enable application-specific customization. Looking ahead, researchers predict that auxetic-structured 3D-printed tactile sensors could underpin next-generation wearable electronics, delivering continuous, high-fidelity monitoring of movement, posture, and health metrics. As additive manufacturing scales, mass-customized tactile systems may soon become standard across consumer electronics, healthcare, and robotics—ushering in a new era of programmable, high-performance sensing.