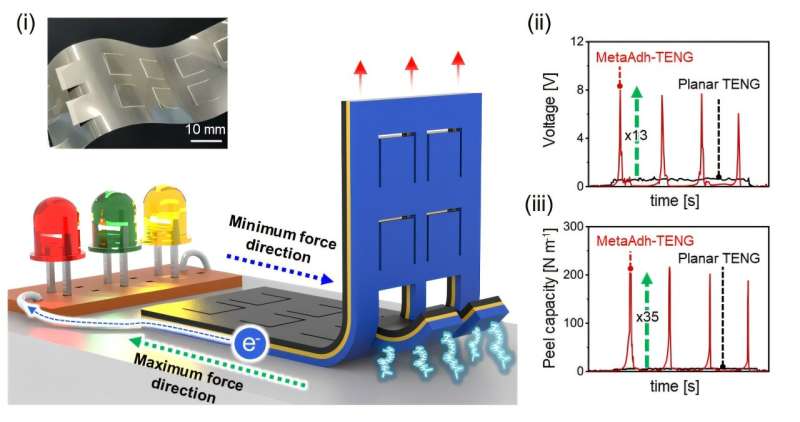

Using smart cut patterns, the ultra-thin film delivers 35× stronger adhesion and 13× more power than conventional designs, enabling self-powered sensors for doors, conveyor belts, and even falling picture frames.

Researchers at the Ulsan National Institute of Science and Technology (UNIST) have developed an ultra-thin, transparent adhesive film that generates electricity simply by peeling or pressing. This could eliminate the need for batteries in safety, security, and industrial monitoring sensors.

At its core, the material—dubbed a metamaterial adhesive-integrated triboelectric nanogenerator (MetaAdh-TENG)—leverages triboelectricity, the phenomenon where charges are created as two surfaces contact and separate. The result is a self-powered sensor that transforms routine mechanical actions into strong electrical signals.

The innovation lies in the film’s cut design. Instead of relying on standard flat adhesives, the researchers engineered nonlinear cuts patterned in the shape of the Korean alphabet “ㄷ”, dramatically enhancing both adhesion and power output. Tests showed adhesion strength improved more than 35 times, while electrical generation increased 13-fold compared to conventional films.

“The cut pattern guides crack propagation, allowing controlled separation and maximum energy output,” explained first author Hee Jin Lee. “When a crack halts at a junction and reverses direction, it produces a surge in electrical signal.”

Beyond simple energy harvesting, the patterned cuts also allow programmable responses. By adjusting the direction or orientation of the cuts, researchers can tailor when and how signals are generated—whether during peeling, pressing, or reverse motion.

The team showcased the film’s versatility through practical demonstrations: when mounted on a door frame, it generated a warning signal each time the door opened; placed behind a picture frame, it triggered an alert before the frame could fall; and when integrated into a conveyor belt, it detected reverse rotation exclusively, enabling early identification of mechanical faults and automatic shutdown of the system.

Professor Hoon Eui Jeong, who led the project, said the technology effectively transforms ordinary adhesive tape into a smart sensing platform. With no need for external power, the film could find use in wearable electronics, anti-theft systems, and predictive maintenance in factories. By merging mechanical design with triboelectric nanogeneration, the team has created a programmable, battery-free sensing solution—one that makes adhesive film not just sticky, but intelligent.