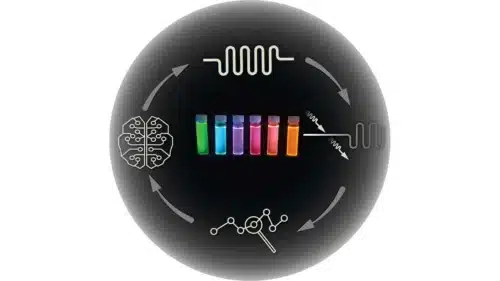

A self-driving laboratory combining ML and automation performs very fast, accurate and continuously without any break.

At North Carolina State University, researchers have demonstrated an AI-powered self-driving lab, combining machine learning algorithms and automation to collect at least 10 times more data than conventional techniques, allowing to identify suitable materials for specific applications in a few months or weeks, while reducing cost drastically.

Until now, traditional materials discovery takes years to generate the final output , using a method called steady-state flow, where the self-driving lab waits each time for chemical reactions to take place before characterizing the resulting materials and also for the ML algorithm to predict the next experiment to conduct.

The new technology “dynamic state flow” enables multiple experiments, where, instead of running separate samples through the system and testing them one at a time after reaching steady-state. This self-driving lab’s ML algorithm is smarter, faster in making decisions and in selecting the optimal materials for the process in a fraction of time, basically a system that essentially never stops running.

In this demonstration, the AIpowered lab was experimented on Cadmium Selenide (CdSe) colloidal quantum dots, the system was able to find the best performing CdSe formulation in the first try after training.

The chemical mixtures are varied in real time, and sensors collect continuous data while the reactions are still in progress. This provides a more detailed flow of information, than a single point data, thus makes the system run accurately and to take 10 times faster decisions.

With this method, researchers can discover optimal materials for clean energy, electronics, and sustainable chemicals and start to test the materials within two to three days, with less chemical wastes.