A new series of multi-turn, surface-mount cermet trimmers offers a space-saving design, wide operating temperature range, and IP67 sealing, making them ideal for industrial, consumer, and telecom applications in harsh environments.

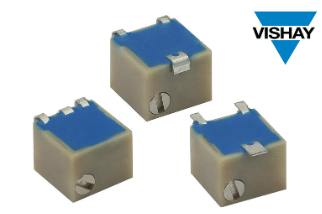

Vishay Intertechnology, Inc. has introduced the TSM3 series, a new line of multi-turn, surface-mount cermet trimmers designed to meet the demanding requirements of industrial, consumer, and telecommunications applications. These trimmers are specifically engineered for use in environments where both space efficiency and long-term durability are essential.

The series has compact design, with dimensions measuring just 3 mm x 4 mm x 4 mm. Despite their small size, these trimmers are built to deliver reliable performance across a wide operating temperature range, from as low as -65 °C to as high as +150 °C. This makes them suitable for use in extreme environmental conditions where temperature fluctuations could otherwise impact the stability and functionality of electronic components.

The series has an IP67-rated sealing, providing a high level of protection against dust, moisture, and other environmental contaminants. This feature ensures that the trimmers can withstand exposure to harsh conditions, making them an ideal choice for applications requiring long-lasting and dependable performance in challenging settings.

Compared to previous trimmer models, the series introduces several significant improvements. It offers a 25% reduction in case size, contributing to more efficient PCB space use in densely packed electronic designs. The series extends the operating temperature range, providing enhanced flexibility and reliability across a broader spectrum of applications.

The key features include:

- Wide resistance range: 10 Ω to 2 MΩ for precise adjustments

- Faster setting-to-time ratio than single-turn trimmers

- Power rating of 0.125 W at 70 °C

- Available in top and side adjustment configurations for design flexibility

Designed with efficiency in mind, the TSM3 series is compatible with automated PCB assembly and setting processes, streamlining production while reducing time and costs. Fully sealed to endure standard board washing procedures, the trimmers ensure reliable performance in various applications, including automation controls, sensors, welding and cooling systems, robotics, power tools, smoke detectors, radios, and precision testing instruments. Samples and production quantities of the series are currently available, with standard lead times of 15 weeks.

For more information, click here.