Researchers show that nanometre-thin germanium on silicon enables high charge mobility, supporting energy-efficient operation of classical and quantum semiconductor devices on standard fabrication platforms.

As electronic devices shrink and power demands grow, traditional silicon semiconductors are reaching physical limits due to higher energy dissipation. Researchers are exploring materials that combine high electrical performance with compatibility for existing chipmaking processes.

A team from the University of Warwick and the National Research Council of Canada has developed a nanometre-thin, compressively strained germanium layer on silicon, achieving record-breaking electrical charge mobility. The study was published in Materials Today.

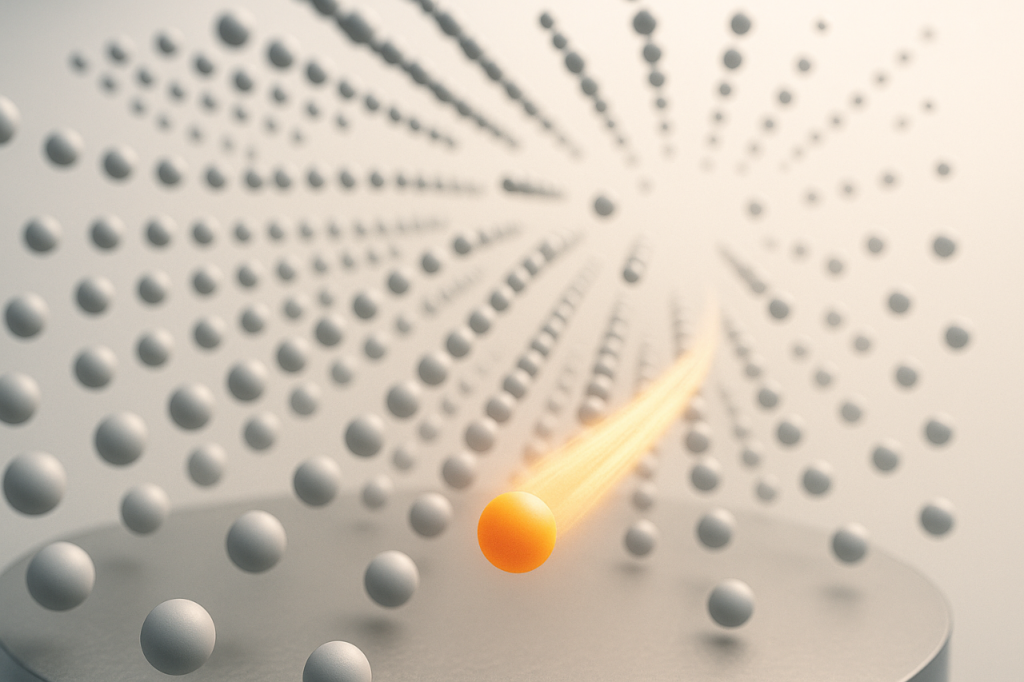

The breakthrough was achieved by carefully engineering the germanium epilayer with precise strain, creating an ultra-clean crystal structure that allows electrical charge to move almost without resistance. The material demonstrated a record hole mobility of 7.15 million cm² per volt-second, far exceeding conventional silicon, enabling faster operation and lower energy consumption.

This compressively strained germanium-on-silicon material combines world-leading mobility with industrial scalability, making it compatible with modern silicon semiconductor manufacturing. It provides a practical pathway for next-generation electronics, including quantum computing devices, spin qubits, cryogenic controllers, AI processors and data-centre hardware with reduced energy and cooling demands.

Key features of the research include:

- Hole mobility of 7.15 million cm²/V·s

- Nanometre-thin germanium epilayer on silicon

- Ultra-clean crystal structure for near-frictionless charge flow

- Compatible with mainstream silicon semiconductor processes

- Enables faster, more energy-efficient classical and quantum devices

Dr Sergei Studenikin, Principal Research Officer, National Research Council of Canada, says, “This sets a new benchmark for charge transport in group-IV semiconductors and opens the door to faster, more energy-efficient electronics fully compatible with existing silicon technology.”