A next-generation capacitor family is setting a new bar for high-current DC link designs, pushing continuous operation to 105 °C without derating and supporting denser, higher-efficiency power conversion systems.

A fresh entrant in the world of power electronic components by TDK Corporation is turning heads with a mix of thermal resilience and electrical muscle. Engineers designing high-power converters from SiC-based inverters to renewable power systems are increasingly constrained by the thermal limits of traditional DC-link capacitors, which typically begin losing rated performance above about 90 °C. The new series changes that narrative, sustaining full rated performance continuously at hotspot temperatures up to 105 °C without derating, a capability that directly tackles a key bottleneck in high-current, high-density designs.

The key features are:

- Continuous +105 °C operation without derating

- Very low ESL (~8 nH) for high-frequency switching systems

- High current density and long operational life (≈200,000 h)

- Wide DC voltage range (1350 – 1800 V) with 470 – 880 µF capacitance

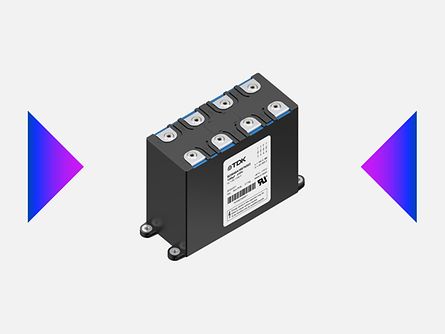

- Modular cube package for easier integration and compact converter layouts

This extended thermal envelope isn’t just a headline figure: it translates into a significant boost in usable current density and lifetimes, helping designers squeeze more power into tighter spaces without sacrificing reliability. Rated lifetimes at the upper temperature threshold are specified at around 200,000 hours a meaningful uptick for systems expected to run hard for years.

Electrical performance is also tuned for modern power electronics. The capacitors support very low equivalent series inductance (ESL), on the order of 8 nH, which makes them particularly suitable for fast-switching silicon carbide (SiC) semiconductor environments where transient behavior is critical. Voltage ratings span from 1350 V up to 1800 V with capacitances from 470 µF to 880 µF covering a broad set of DC-link needs in traction, industrial drives, energy storage and renewable power converters.

The units are built on a modular, cubic form factor that simplifies integration into busbar architectures, easing layout work while helping reduce the array footprint in compact converters. Beyond performance, there’s an eye toward sustainability and safety: dielectric materials carry bio-circular certification, and housings meet key fire standards.