A new compact laser displacement sensor redefines short-range measurement with micron-level accuracy, even on dark, glossy, or irregular surfaces—boosting productivity and reliability across demanding industrial environments.

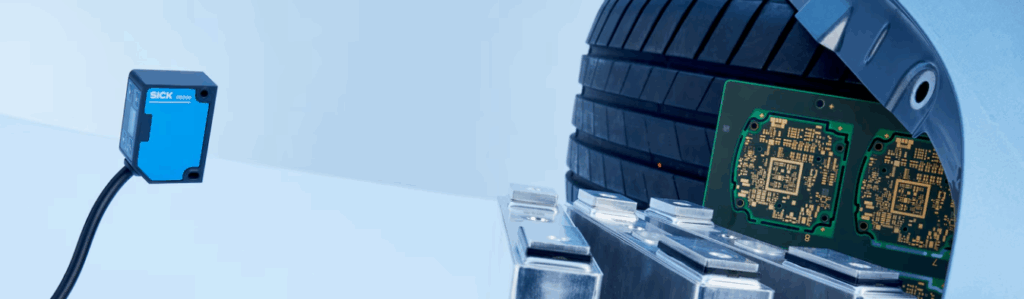

SICK has unveiled the OD200, a compact short-range laser distance sensor engineered for precision measurement in the most demanding industrial environments. Designed with a newly developed triangulation core, high-resolution dynamic receiver system, and an optimized optical setup,it achieves stable, reliable, and repeatable performance even on dark, glossy, or irregular surfaces. The sensor is ideal for applications involving reflective materials such as carbon composites, textured metals, and die castings, where other sensors often falter due to poor light conditions or surface inconsistencies.

The key features are:

- Measuring range: 25 mm to 160 mm

- Repeatability: as low as 2 µm

- High-speed performance: up to 3 kHz process speed

The core strength lies in its ability to deliver high measurement accuracy, even in high-speed production environments. The sensors are ideal for in-line inspection, quality assurance, and assembly verification across industries like automotive, electronics, aerospace, robotics, and consumer goods manufacturing. Its advanced optics ensure reliable detection of low remission or complexly structured surfaces, significantly reducing measurement errors, downtime, and rework.

Ease of integration is a standout feature. With a compact design and plug-and-play compatibility, the it fits seamlessly into tight industrial spaces. It supports all standard interfaces, including IO-Link, analog outputs (current/voltage), and digital I/Os, ensuring smooth deployment in Industry 4.0 environments. An intuitive menu-driven display and SOPAS configuration software streamline installation, calibration, and diagnostics. IO-Link further enhances access, allowing full control even when sensors are mounted in hard-to-reach areas.

Beyond just measuring distance, it contributes to process optimization. The sensor provides real-time data like exposure time and signal peak width, enabling users to monitor performance and conduct predictive maintenance. This continuous feedback helps prevent unplanned downtime and enhances productivity.

Nick Hartley, Product Manager at SICK, summarizes: “The OD200 offers unmatched measurement stability and ease of integration. With its compact housing, fast response, and ability to tackle even the most difficult materials and lighting conditions, it delivers high performance and reliability where other sensors fall short.”