The advancement could mark a turning point in developing sustainable, compact energy sources for the rapidly growing network of IoT devices, offering high performance without the high costs or instability of traditional thermoelectrics.

Hybrid Material Doubles Thermoelectric Efficiency

In a significant leap for thermoelectric technology, an international research team led by Fabian Garmroudi has developed a novel hybrid material that achieves exceptional energy conversion efficiency by decoupling heat and electrical charge transport. Their findings could pave the way for more efficient energy harvesting in miniaturized electronics, particularly for autonomous Internet of Things (IoT) devices.

Thermoelectric materials generate electricity from heat, making them ideal for powering small, remote sensors and electronics. However, one of the main challenges in advancing this technology has been the need to suppress heat conduction while promoting the mobility of charge carriers—a task often limited by the inherent properties of most materials.

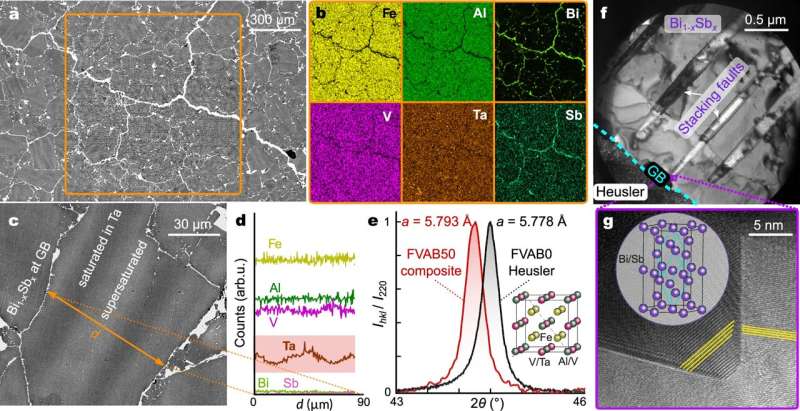

The breakthrough came through combining two materials with contrasting mechanical properties but similar electronic behavior: an alloy composed of iron, vanadium, tantalum, and aluminum (Fe₂V₀.₉₅Ta₀.₁Al₀.₉₅) and a bismuth-antimony mix (Bi₀.₉Sb₀.₁). When compressed at high pressure and temperature, the two components form a compact structure, but remain distinct at the atomic level. The bismuth-antimony is deposited along the grain boundaries of the alloy, where it plays a crucial role in altering thermal and electrical behaviors.

This design effectively disrupts heat transfer at the interfaces due to mismatched atomic vibrations, while allowing charge carriers to move freely. Even more impressively, the BiSb component exhibits topological insulator behavior—insulating internally but conducting electricity almost without resistance along surfaces. This structure accelerates electron flow while severely restricting heat transfer, boosting the material’s thermoelectric efficiency by over 100%.

“This hybrid approach brings us significantly closer to producing thermoelectric materials that can rival or even outperform current industry standards like bismuth telluride,” says Garmroudi. “Plus, our materials are more stable and cost-effective.”