Researchers at Carnegie Mellon University have developed a 3D technique of printing microscale ice structures that can form intricate templates for complex channels.

Image Credits: Carnegie Mellon University.

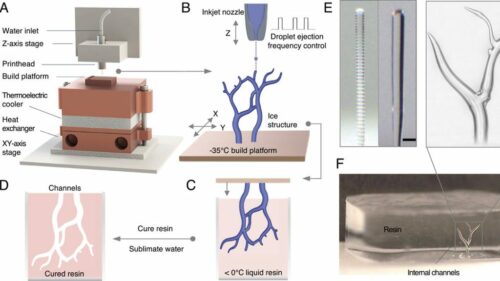

The team has built their own printer to enable ice 3D printing possible. The ‘inside-out’ 3D printing process involves freezing water droplets onto a custom-built platform at a temperature of -31°F. These smooth ice sculptures can be dunked in resin. This leaves the parts with complex internal pathways while melting. The 3D ice printing tech is capable of yielding fully fledged complex networks of liquid conduits. The team also believes that these can be used in building soft robots for a safe and non-invasive interaction with patients.

The ice 3D printer developed by the team has a temperature controlled platform. It is mounted onto an X-Y stage with a MicroFab inkjet printhead. This set up allows creating a smooth surfaced part using the droplet ejection frequency modulation. The acrylic enclosure of the setup prevents frost formation.

The team tested these 3D ice sculptures by attempting to print narrow, leaning pillars. However, many droplets missed their targets due to excessive platform movement. The scientists then developed pre-programmed stage trajectories using the data sets from the previous attempt. With this pre-programmed trajectories, the printer yielded structures with curved geometry and overhangs of up to 80 degree. The researchers then replaced these tests to create more complex 3D geometries to assess their efficacy as sacrificial templates. The team was able to prevent the ice from melting until the parts were finished eventually.

“This is an amazing accomplishment that will bring exciting advances,” added Burak Ozdoganlar, a professor in mechanical engineering at Carnegie Mellon University. “We believe this approach has enormous potential to revolutionize tissue engineering and other fields, where miniature structures with complex channels are demanded, such as for microfluidics and soft robotics.”