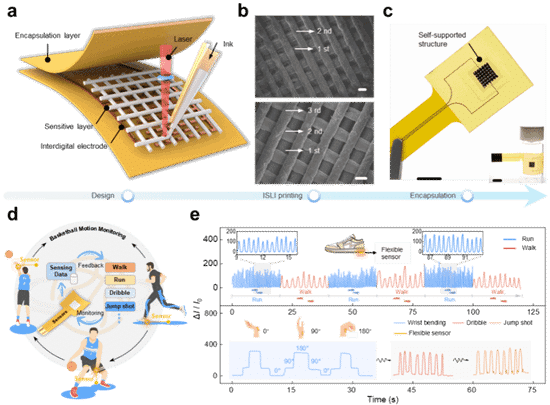

With sub-second solidification, 50-micron resolution, and real-time tuning of mechanical and electrical properties, the approach promises faster, programmable manufacturing for flexible electronics, soft robotics, microfluidics, and biomedical devices.

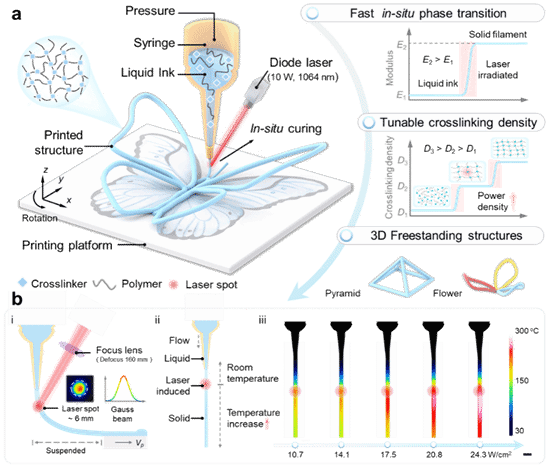

A research team at Xiamen University (XMU) has unveiled a major advance in 3D printing of thermoset materials, a leap that could reshape manufacturing of flexible electronics, soft robotics, biomedical scaffolds and more. The newly developed method, described in a paper titled “Laser-assisted direct three-dimensional printing of free-standing thermoset devices”, integrates in situ laser-induced solidification with direct-ink writing.

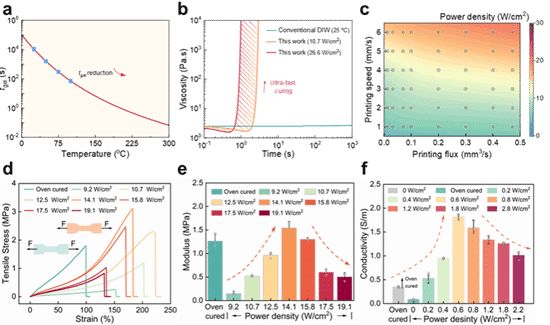

This enables creation of intricate, free-standing thermoset structures without any supporting material, a major improvement over existing methods that often require support and then removal. During printing, a tightly focused laser rapidly cures the polymer jet via a strong photothermal effect, triggering crosslinking in under 0.25 seconds. The process achieves a structural resolution as fine as 50 micrometers, and notably allows real-time tuning of material properties: mechanical modulus can be altered by up to tenfold, while electrical properties can be modulated by up to twentyfold.

This combination of speed, precision, and tunability marks a significant departure from conventional direct-write 3D printing approaches (thermal, acoustic, or UV-assisted), which often suffer from low curing efficiency, limited material compatibility, restricted performance tuning, and dependence on supporting structures.

The implications are broad. Researchers say this “fast, stable, programmable manufacturing strategy” could accelerate the development of complex, multifunctional thermoset devices suited for flexible electronics, microfluidic systems, soft robotics, organ-on-chip platforms, and biomedical scaffolds wherever intricate.3D architectures and bespoke material properties are required. In effect, XMU’s innovation could lower a key barrier in additive manufacturing of thermoset-based devices: by eliminating the need for support materials and enabling on-the-fly control over structural and functional properties, the new method offers a more efficient, scalable, and versatile route for fabricating advanced components in emerging tech domains.