Tuning method that compensates for fabrication errors in 250–300 GHz terahertz devices—paving the way for scalable, ultra-fast 6G wireless systems beyond the limits of conventional CMOS technology.

Researchers from Science Tokyo and Hiroshima University have developed a precision mechanical tuning method using microactuators to address critical design challenges in terahertz (THz) wireless systems operating at frequencies above 100 GHz, particularly at 250–300 GHz.

At such high frequencies, even tiny mechanical fabrication errors—on the order of ±50 μm—can severely impact device performance. These tolerances are insignificant at sub-6 GHz but represent up to 5% of the wavelength at 300 GHz, causing impedance mismatches and signal degradation, especially at the chip-to-antenna interface. Traditional CMOS transistors can’t handle these ultra-high frequencies, ruling out electronic tuning. The team’s innovative solution replaces active circuitry with mechanical actuation, offering precision without relying on high-speed electronics.

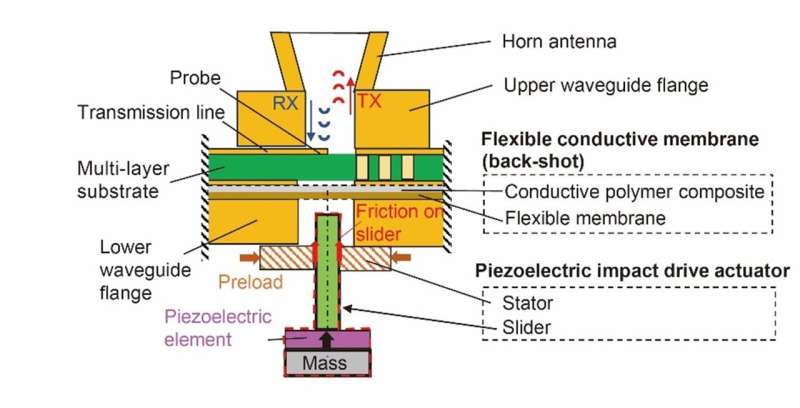

The approach enables consistent, high-performance THz transmission—even with inherent fabrication variations—making scalable, next-gen terahertz wireless systems more feasible. Instead of redesigning the chip or antenna, manufacturers can now compensate post-fabrication using this fine-tuning mechanism. The method borrows from optical systems: like a camera adjusts lens position for focus, the THz device uses a flexible conductive membrane as a movable backshort (reflector) within the waveguide. A micro-scale impact-drive actuator slides the membrane to adjust impedance with sub-micron precision.

This allows real-time, high-accuracy impedance tuning in the 250–300 GHz range, critical for minimizing signal loss and distortion during transmission. The entire structure is compact, CMOS-compatible, and free from active circuit limitations. This is a promising step toward reliable THz systems, ideal for ultra-fast wireless communications such as 6G, ultra-HD streaming, or chip-to-chip data transfer in future smart devices and edge AI platforms.

By proving that mechanical tuning can correct for manufacturing imperfections in terahertz modules, the researchers have opened a scalable, practical path forward for the next leap in wireless speed and capacity—without being bottlenecked by traditional semiconductor constraints.Mechanical precision may just be the key to unlocking the full potential of ultra-wideband terahertz wireless systems.