Rising power densities and harsh operating conditions are driving demand for potting compounds that protect electronics without slowing manufacturing processes.

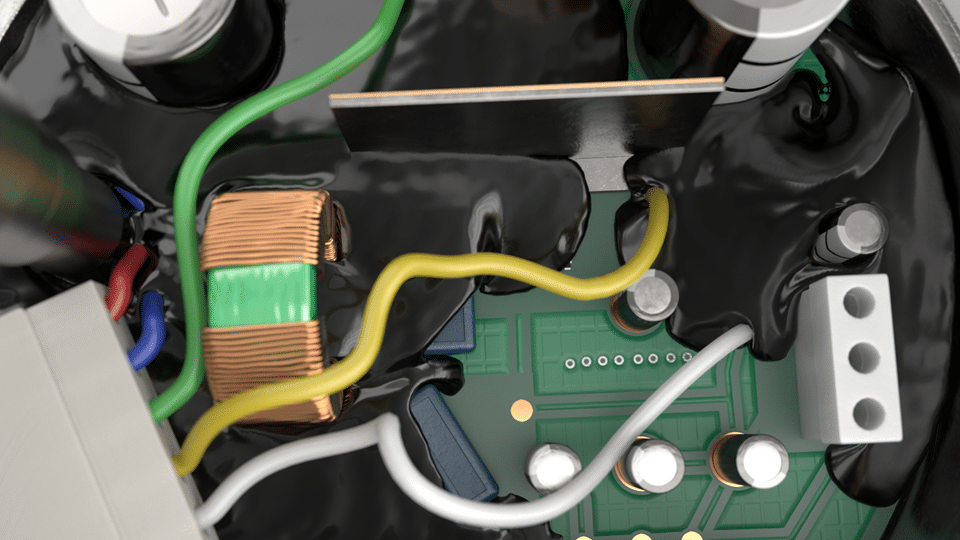

As industrial and power electronics operate in increasingly harsh environments, manufacturers face growing challenges related to heat, humidity, vibration, and long term reliability. Systems such as motor drives, inverters, power supplies, battery management units, and industrial sensors must perform consistently despite risks of corrosion, insulation failure, and premature degradation. These pressures are driving demand for advanced potting materials that protect sensitive electronics while supporting efficient manufacturing.

Henkel is addressing this need with the launch of Loctite STYCAST US 8000 A B, a next generation two component polyurethane potting compound designed for demanding industrial and power electronics applications. The solution expands Henkel’s high performance electronics protection portfolio, delivering strong electrical insulation, mechanical durability, and long term stability under extreme operating conditions.

The material features ultra low ionic content below 20 ppm, reducing corrosion and preventing silver migration in high humidity environments. It carries a UL 746 relative temperature index of 140 degrees Celsius and a UL 94 V 0 flammability rating, ensuring thermal endurance and safety compliance. Electrically, it provides high dielectric strength and maintains surface insulation resistance even after prolonged exposure to heat and moisture.

Designed for manufacturing efficiency, the compound offers low mixed viscosity and a standard 4 to 1 mix ratio, enabling smooth dispensing and void free encapsulation in complex assemblies. It supports both room temperature and accelerated heat curing, offering process flexibility while maintaining resilience against vibration and thermal expansion.

Key features of the glue include:

- Ultra low ionic content for corrosion and silver migration resistance

- High dielectric strength and long term insulation stability

- UL certified thermal endurance and flame resistance

- Low viscosity for void free potting in complex geometries

- Flexible curing options for efficient manufacturing

Eric Zhai, Global Senior Market Strategy Manager for Power and Industrial Automation at the company says, “At Henkel, we are committed to enabling the next generation of reliable and energy efficient electronic systems. With Loctite STYCAST US 8000 A B, we are expanding our advanced protection portfolio to help customers meet increasingly demanding environmental and compliance requirements.”