Researchers at the Institute for Basic Science have developed a novel method for recycling valuable metals from used lithium-ion batteries.

The shift towards lithium-ion batteries as a new energy storage option has led to a surge in lithium battery waste, adding to the existing problem of carbon-based energy. Over time, lithium-ion batteries degrade, losing up to 24% of total capacity over 500 cycles. Battery disposal in landfills or incineration poses environmental and safety risks due to toxic elements. Recycling lithium batteries is complex and expensive due to multiple extraction-stripping steps in separate reactors with different parameters, resulting in a low recycling rate.

Researchers at the Center of Soft and Living Matter within the Institute for Basic Science (IBS), South Korea, have developed a novel method for recycling valuable metals, such as lithium, nickel, and cobalt, from spent lithium-ion batteries.

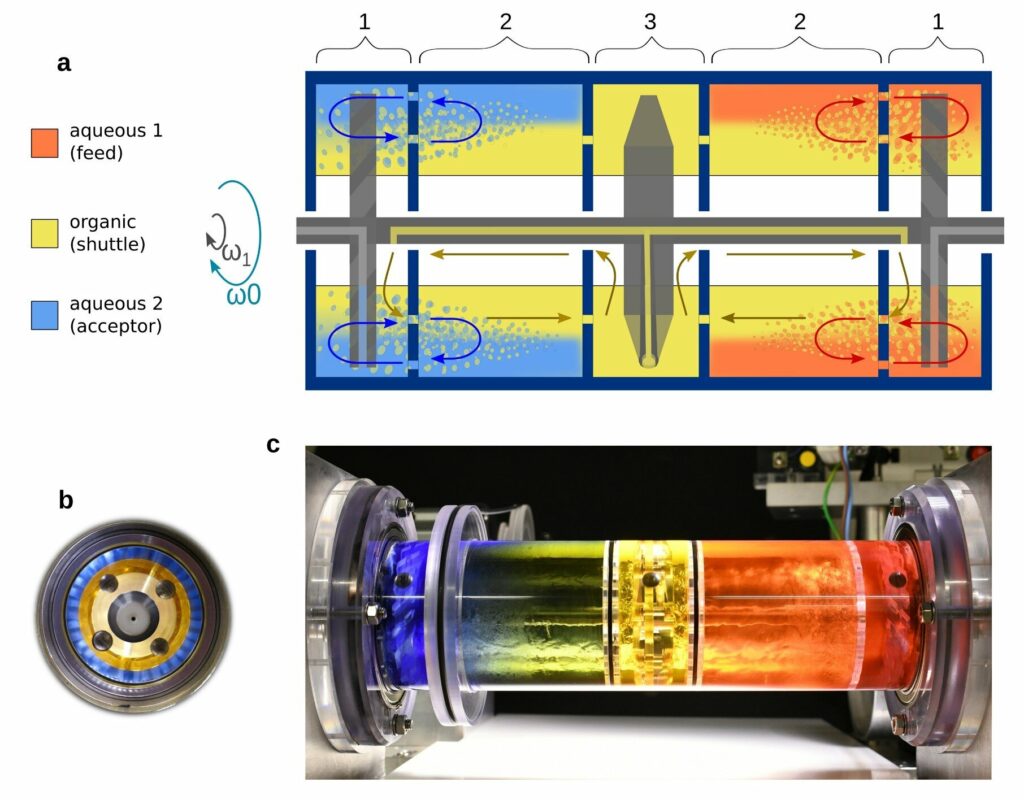

The team have designed a horizontally rotating reactor that can handle complex metal mixtures containing aqueous feed, organic extractant, and aqueous acceptor phases in a single rotating vessel. This reactor differs from one-pot setups that use membranes as it can be vigorously stirred and emulsified without causing the aqueous layers to merge. The reactor’s design maintains the arrangement of higher-pH feed, organic extractant (shuttle), and lower-pH acceptor phases by arranging them in concentric layers that are stable enough to facilitate efficient interfacial mixing while preventing the coalescence of aqueous layers.

According to the researchers, the process is impressive in that it can separate metals within a few minutes using a low concentration of extracting agents and with high selectivity. The study showcases that concentric liquid reactors, particularly the segmented variations, can quickly extract valuable metals from highly concentrated mixtures using considerably lower extractant concentrations than current methods. Furthermore, these reactors can explore uncharted territories of process parameters.

Concentric liquid reactors offer an intriguing alternative to traditional hydrometallurgical methods due to their favorable power-to-operate scaling relative to reactor size. These factors, combined with the ability to extract other valuable metals, make them suitable for various separation applications. The researchers highlight that the technology’s versatility is forward-looking, as it can be adjusted to accommodate different feed metal compositions and extract metals other than those used in batteries.

Reference : Cristóbal Quintana et al, One‐Pot, Three‐Phase Recycling of Metals from Li‐Ion Batteries in Rotating, Concentric‐Liquid Reactors, Advanced Materials (2023). DOI: 10.1002/adma.202211946